Introduction

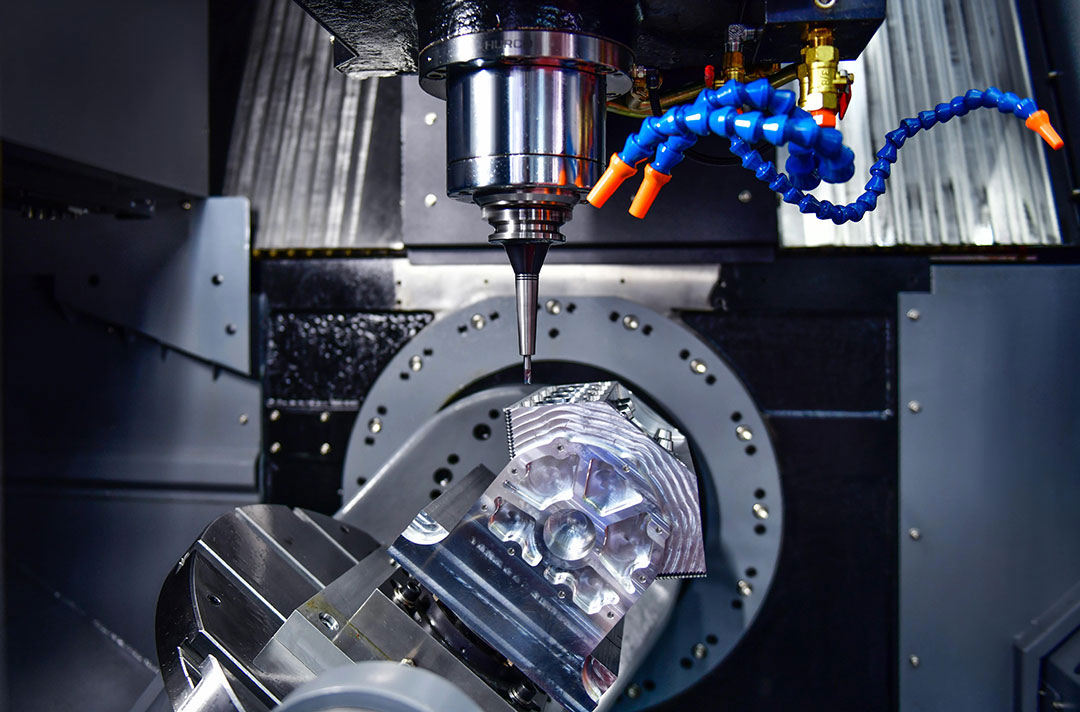

CNC (Computerized Numerical Control) machining is an advanced manufacturing technology that uses computer control and occupies an important position in the field of mechanical machining. It can achieve high-precision and high-efficiency parts machining and is widely used in a variety of industries such as aerospace, automobile manufacturing, mold manufacturing, and electronic equipment. With the continuous development of the manufacturing industry, the requirements for part quality and production efficiency are getting higher and higher. In-depth understanding of the CNC machining process is of great significance for optimizing the production process, improving product quality, and reducing production costs.

Overview of CNC machining process

Design stage

Product design and modeling

(1) Product design is the starting point of the entire processing process. Designers use computer-aided design (CAD) software to create a three-dimensional model based on the product’s usage requirements, functional performance and design. In CAD software, designers can accurately define the shape, size, features and assembly relationships of parts.

(2) Commonly used CAD software include AutoCAD, SolidWorks, Pro/Engineer, etc. These software provide rich functions and support parametric design, which makes it convenient for designers to modify and improve parts. During the design process, the feasibility of the processing technology must also be considered to avoid designing structures that are difficult to process or too costly.

Process planning and analysis

(1) Process planning is to develop a reasonable processing plan based on the design requirements of the parts. Process planners need to consider factors such as the material, shape, dimensional accuracy, and surface roughness of the parts.

(2) First, the processing route must be determined, including the selection of appropriate processing methods (such as turning, milling, drilling, etc.), processing sequence and processing equipment. Secondly, the cutting parameters must be determined, such as cutting speed, feed rate, cutting depth, etc. The selection of these parameters will directly affect the processing efficiency and part quality. At the same time, the selection of tools must also be considered, and the appropriate tool type and size must be selected according to the part material and processing requirements.

Programming stage

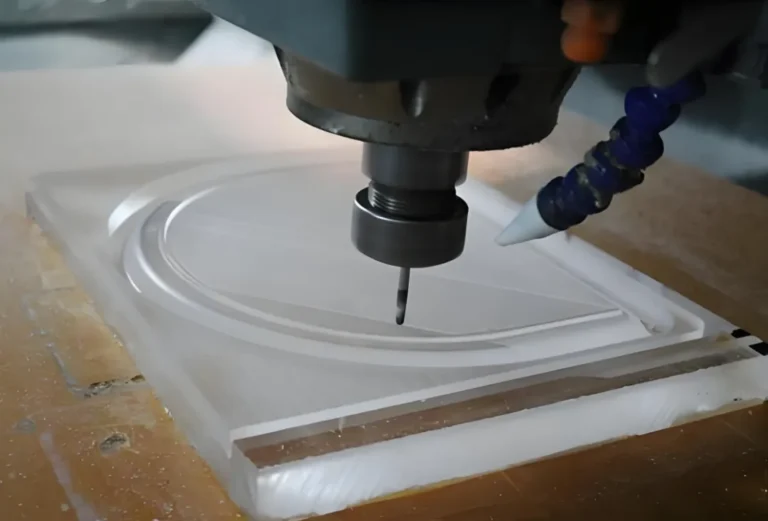

Tool path planning

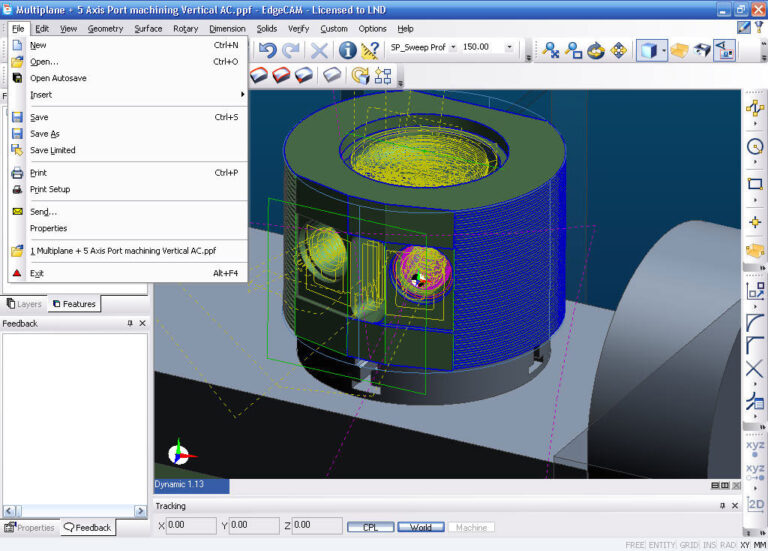

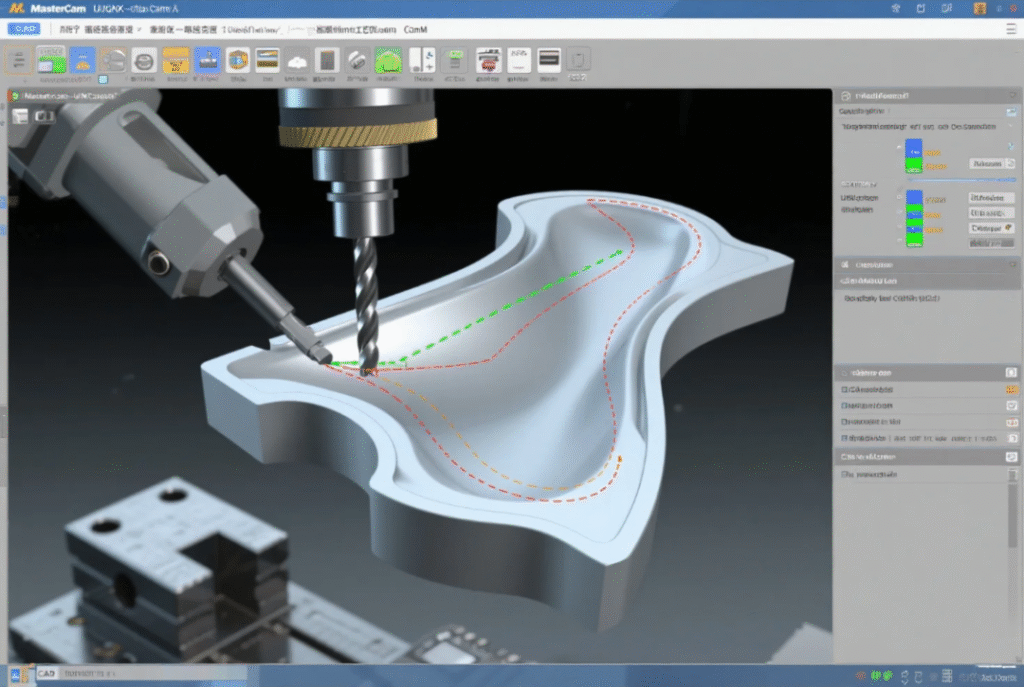

(1) After the machining process is determined, tool path planning is required. Tool path planning is to plan the movement trajectory of the tool during the machining process based on the geometric shape of the part and the machining requirements. This step is usually completed in computer-aided manufacturing (CAM) software.

(2) CAM software can import CAD models and automatically generate tool paths based on process parameters. For example, when machining a three-dimensional curved surface part, CAM software can generate a tool path along the curved surface based on set parameters such as cutting layer depth and step length. Tool path planning needs to consider the tool’s entry and exit methods to avoid collisions between the tool and the part or fixture.

(3) Commonly used CAM software include Mastercam, UG NX, Catia, etc. These software provide a variety of tool path strategies, such as high-level line processing, spiral line processing, reciprocating processing, etc., which are suitable for different processing scenarios.

Generate NC program code

(1) Based on the planned tool path, CAM software can generate the corresponding NC (Numerical Control) program code. NC program code is a set of instructions that can be recognized by a computer and is used to control the movement and processing operations of CNC machine tools.

(2) Different CNC machine tool control systems (such as FANUC, SIEMENS, HAAS, etc.) have different NC program code formats and set instructions. When generating NC program codes, you need to set them according to the specific machine tool control system. For example, the NC program codes of the FANUC system are usually based on G codes and M codes, where G codes are used to control the trajectory of tool movement and processing methods, and M codes are used to control the auxiliary functions of the machine tool, such as starting and stopping the spindle, switching the coolant, etc.

Processing preparation stage

1.Preparation of fixtures

Fixtures are devices used to clamp and position workpieces. In CNC machining, suitable fixtures can ensure the machining accuracy and stability of the workpiece. Common fixtures include three-jaw chucks, four-jaw chucks, flat-nose pliers, vacuum clamps, etc. Select the appropriate fixture according to the shape of the part and the machining requirements, and adjust and calibrate it.

2.Tool preparation and installation

According to the requirements of process planning and NC program code, prepare the corresponding tools, install and debug them. The installation of the tools needs to ensure that the tools are clamped reliably and the extension length of the tools is appropriate to avoid vibration or breakage of the tools during processing. At the same time, the tools should be pre-adjusted, and the tool dimensions and tool length compensation values should be measured. The tool length compensation value is used to compensate for tool wear and length changes after the new tool is replaced to ensure the accuracy of the processing dimensions.

Processing stage

1.Machine tool setting and debugging

(1) Before starting processing, a series of settings and debugging work needs to be done on the CNC machine tool. First, the machine tool needs to be started and initialized, including checking the machine tool’s lubrication system, cooling system, spindle operation, etc., to ensure that the machine tool is in normal working condition.

(2) Then, set the coordinate system of the machine tool according to the processing requirements. For example, by manually setting the tool or using a tool setting instrument, determine the origin position of the workpiece coordinate system so that the machine tool can accurately perform processing according to the NC program code. At the same time, set the tool parameters of the machine tool, such as the type, size, and tool length compensation value of the tool.

(3) It is also necessary to adjust the processing parameters of the machine tool, such as spindle speed, feed speed, cutting depth, etc., to match them with the instructions in the NC program code. During the debugging process, a dry run test can be performed, that is, the machine tool performs simulated processing according to the NC program code without clamping the workpiece and tool, to check whether the tool path is correct and whether the machine tool will have abnormal situations such as collision or overtravel.

2.Process monitoring and intervention

During the machining process, the operating status and machining conditions of the machine tool need to be closely monitored. The operator can observe the cutting status of the tool, the flow of the cutting fluid, the running sound of the spindle, etc. through the machine tool control panel. If abnormal conditions are found, such as tool wear, excessive cutting force, and machining size deviation, timely measures can be taken to intervene.

Key elements in CNC machining process

Tool selection

The tool is the tool that directly contacts the workpiece during CNC machining. Its performance and quality have a direct impact on machining efficiency and part quality. Tool material, geometry, size and other factors need to be reasonably selected based on the machining material and machining requirements.

1.Material selection

(1) Common tool materials include high-speed steel, cemented carbide, ceramics, cubic boron nitride (CBN) and diamond. High-speed steel tools have good toughness and are suitable for processing occasions with low cutting speeds, such as rough processing and cutting tough materials. Cemented carbide tools have high hardness and good wear resistance and are suitable for medium and high-speed cutting and processing of materials with higher hardness.

(2) Ceramic tools have high hardness and heat resistance and are suitable for high-speed cutting and processing of materials such as cast iron and steel. Cubic boron nitride tools and diamond tools are mainly used for processing superhard materials such as cemented carbide and ceramics.

2.Geometry and size selection

The geometric shape of the tool includes the shape of the tool tip, the main deflection angle, the secondary deflection angle, the rake angle, etc. Different geometric shapes are suitable for different processing requirements. For example, a larger main deflection angle can reduce the radial cutting force and is suitable for processing deep holes; the choice of rake angle will affect the discharge direction of the cutting chips. For different processing methods and workpiece materials, it is necessary to select a suitable rake angle. The size of the tool should be determined according to the processing size and shape of the part.

Cutting parameter optimization

Cutting parameters include cutting speed, feed rate and cutting depth. A reasonable combination of them can improve machining efficiency and part quality.

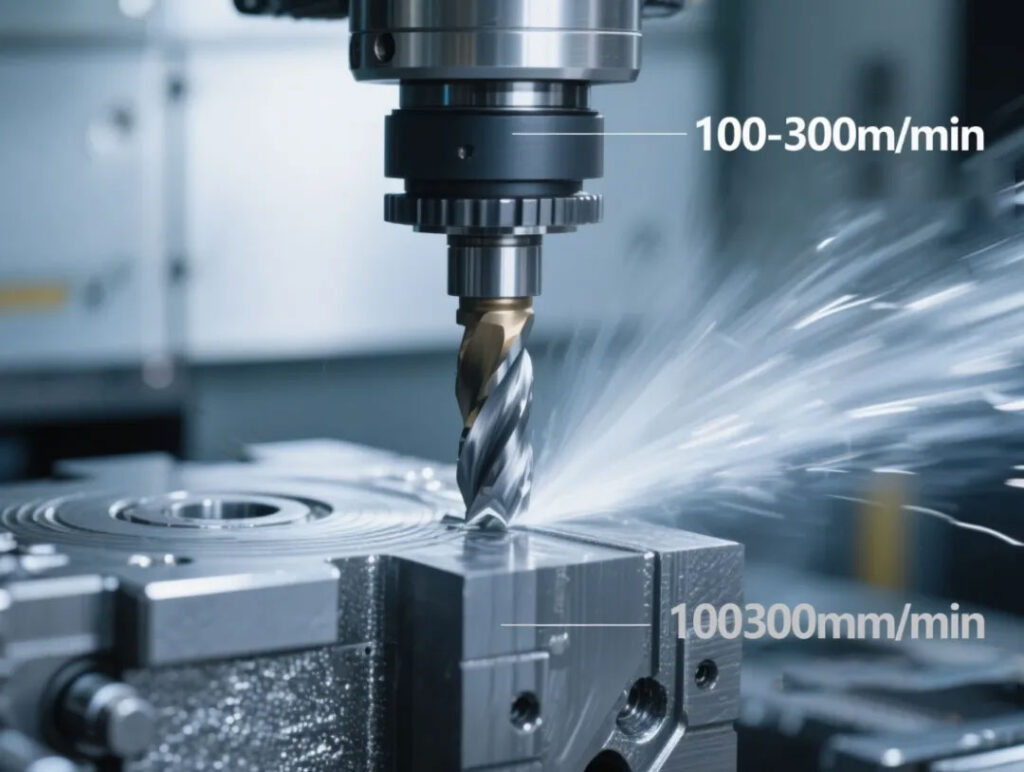

1.Cutting speed

Cutting speed is the relative speed between the tool and the workpiece. Its selection mainly depends on factors such as tool material, workpiece material and tool life. Generally speaking, the cutting speed of carbide tools can reach 100-300m/min when processing steel parts; and the cutting speed can be higher when processing cast iron. Increasing the cutting speed can increase the material removal rate, but it will also increase tool wear and cutting temperature, which may lead to a shortened tool life and a decrease in part surface quality. Therefore, it is necessary to reasonably select the cutting speed while ensuring the processing quality and tool life.

2.Feed rate

Feed rate refers to the distance the tool moves relative to the workpiece per revolution or per minute. The selection of feed rate should take into account factors such as part machining accuracy, surface roughness and tool strength. A smaller feed rate can achieve higher surface quality, but lower machining efficiency; a larger feed rate can improve machining efficiency, but may lead to increased surface roughness of parts and increased tool wear.

3.Cutting depth

Cutting depth refers to the depth of the tool into the workpiece. The selection of cutting depth should be determined according to the machining allowance of the part and the strength of the tool. A larger cutting depth can reduce the number of processing times and improve processing efficiency, but it will generate greater cutting force on the tool, which may cause the tool to deform or break.

Processing accuracy control

Precision control of CNC machining is a key link in ensuring part quality, including aspects such as geometric accuracy, dimensional accuracy and surface roughness.

1.Geometric accuracy control

Geometric accuracy mainly refers to the shape accuracy and position accuracy of parts, such as straightness, flatness, roundness, verticality, parallelism, etc. In the processing process, the geometric accuracy can be effectively controlled by rationally selecting machine tools, cutting tools, fixtures and processing technology. At the same time, in the processing process, we should follow the principle of roughing first and then fine, and benchmarking first and then other things, to ensure that the processing sequence of parts is reasonable and reduce the cumulative error. In addition, regular precision testing and calibration of machine tools is also an important measure to ensure geometric accuracy.

2.Dimensional accuracy control

Dimensional accuracy is one of the most important quality indicators in parts processing. There are many factors that affect dimensional accuracy, such as tool wear, thermal deformation, machine tool accuracy, measurement error, etc. During the processing, effective measures should be taken to control dimensional accuracy.

Surface roughness control

(1) Surface roughness reflects the degree of microscopic unevenness on the surface of a part, which has an important influence on the wear resistance, corrosion resistance, and matching performance of the part. Surface roughness is mainly affected by factors such as cutting speed, feed rate, tool geometry, and cutting fluid.

(2) In order to obtain good surface roughness, appropriate cutting parameters can be selected, such as increasing the cutting speed and reducing the feed rate; optimizing the tool geometry, such as using a smaller rake angle and a larger front angle; and using cutting fluid reasonably can reduce the cutting temperature and reduce friction during the cutting process, thereby improving the surface roughness.

Optimization of CNC machining process

Process innovation and improvement

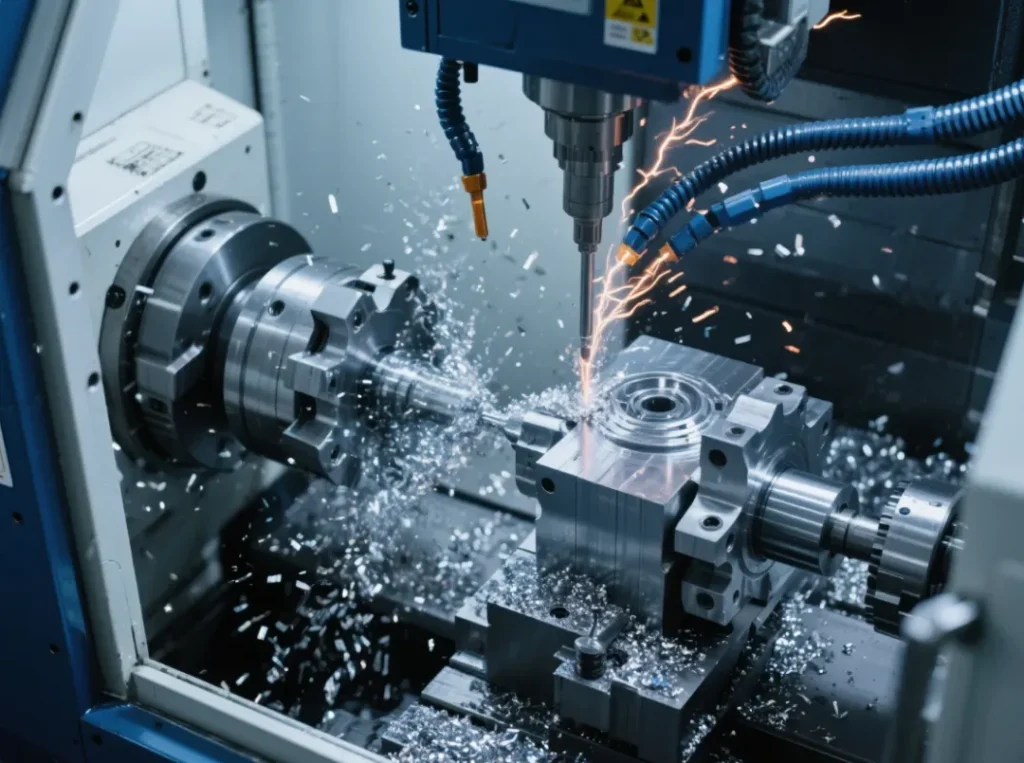

1.Application of composite processing technology

Compound machining technology refers to the integration of multiple machining methods into one machining process, such as turning-milling compound, milling-EDM compound machining, etc. Compound machining technology can reduce the number of workpiece clamping times and machining time, and improve machining efficiency and part quality.ining technology can reduce the number of workpiece clamping times and machining time, and improve machining efficiency and part quality.

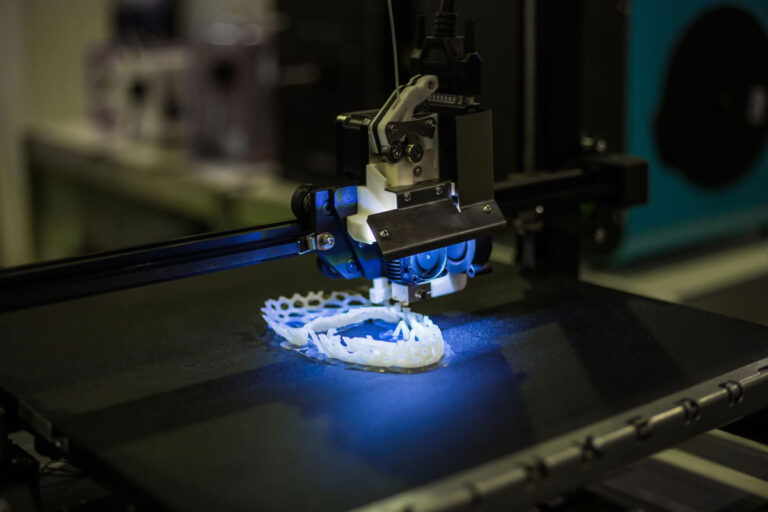

2.Application of new CNC machining technologies

With the continuous development of numerical control technology, some new processing technologies are gradually applied to the field of CNC processing, such as high-speed processing, precision processing, micro-nano processing, etc. High-speed processing technology can greatly improve material removal rate and processing efficiency, while obtaining better surface quality. Precision processing and micro-nano processing technologies can meet the needs of aerospace, electronic information and other fields for high-precision and small-sized parts. The application of these new technologies requires adjustment and optimization of the original processing process to give full play to their advantages.

Application of simulation and emulation technology

1.Process simulation and simulation

(1) Process simulation and simulation technology can simulate the entire CNC machining process through computers, including tool path, cutting force, cutting temperature, tool wear and other aspects. Before machining, simulation and simulation can predict possible problems in the machining process, such as tool collision, overcutting, vibration, etc., so as to adjust the machining process parameters and tool path in time and optimize the machining process.

(2) For example, using processing simulation software such as Vericut, NC programs can be verified and optimized to reduce errors and scrap rates during processing. Process simulation and simulation technology can also help operators better understand the processing and improve their operating skills.

2.Quality prediction and control simulation

Quality prediction and control simulation is to predict the quality indicators of parts during the processing (such as dimensional accuracy, surface roughness, etc.) by establishing mathematical models and computer simulations, and to perform quality control based on the prediction results. Before processing, the quality status of parts is predicted using quality prediction models based on the design requirements and processing parameters of the parts, and measures are taken in advance to adjust and optimize the process.

Conclusion

The CNC machining process is a complex and systematic project, involving multiple stages such as design, programming, machining preparation, and machining. Reasonable design, optimized process planning, accurate programming, sufficient machining preparation, and effective machining monitoring are the key to ensuring the quality of CNC machining. With the continuous development and innovation of CNC technology, the CNC machining process is also being continuously optimized and improved. By introducing composite machining technology, new CNC machining technology, simulation and simulation technology, the efficiency and quality of CNC machining can be further improved to meet the needs of modern manufacturing for high-precision, high-quality, and high-efficiency parts machining. In the future, CNC machining technology will develop in a more intelligent, automated, and precise direction, providing stronger support for the development of the manufacturing industry.