1.What is Design for Function (DFM)?

The full name is “Design For Manufacturing”, which means “parts processing-oriented”. Through process feature design, the difficulty of part processing and the cost of part manufacturing can be reduced.

2.Why do we need to carry out DFM?

The purpose of DFM is to ensure smooth production, identify errors in the R&D to production process in advance, avoid some erroneous designs, unreasonable designs, anti-human designs, etc. in the R&D stage from failing in production, reduce process losses, and improve process efficiency.

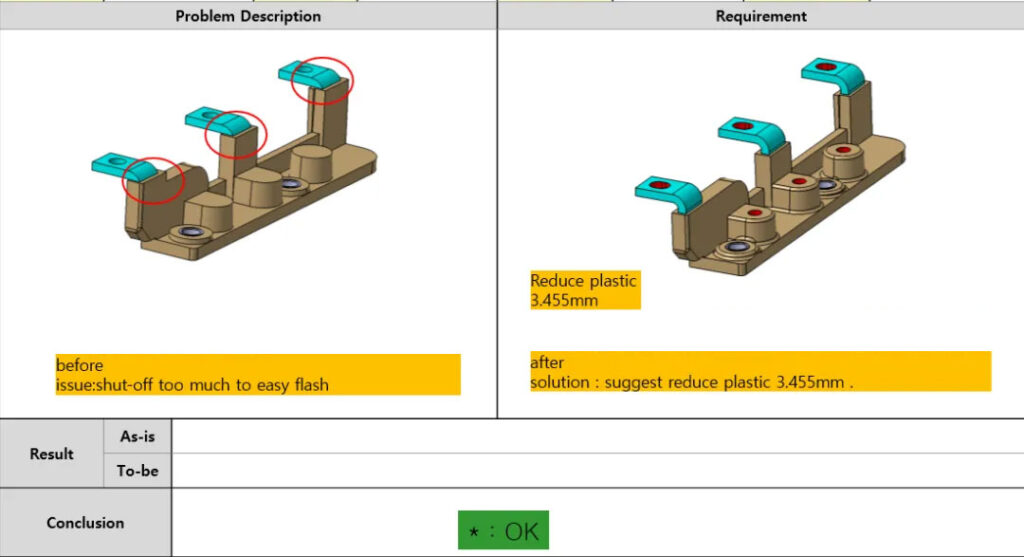

For example, for a part like the one shown in the figure, the mold engineer anticipated the flashing issues that could occur due to injection molding and provided reasonable suggestions. The customer adopted the suggestions, modified the data, and mass production was possible.

3.At which stages is DFM required?

Generally, DFM analysis is required wherever there is analysis, design and review.

I’d like to add that the part feasibility analysis report typically produced after a new project RFQ is called a “TR,” not a “DFM.” I’ll explain this later.

4.How to perform DFM?

To conduct a DFM analysis, you need to follow these steps:

Determine the analysis object: Select the product or component that needs DFM analysis.

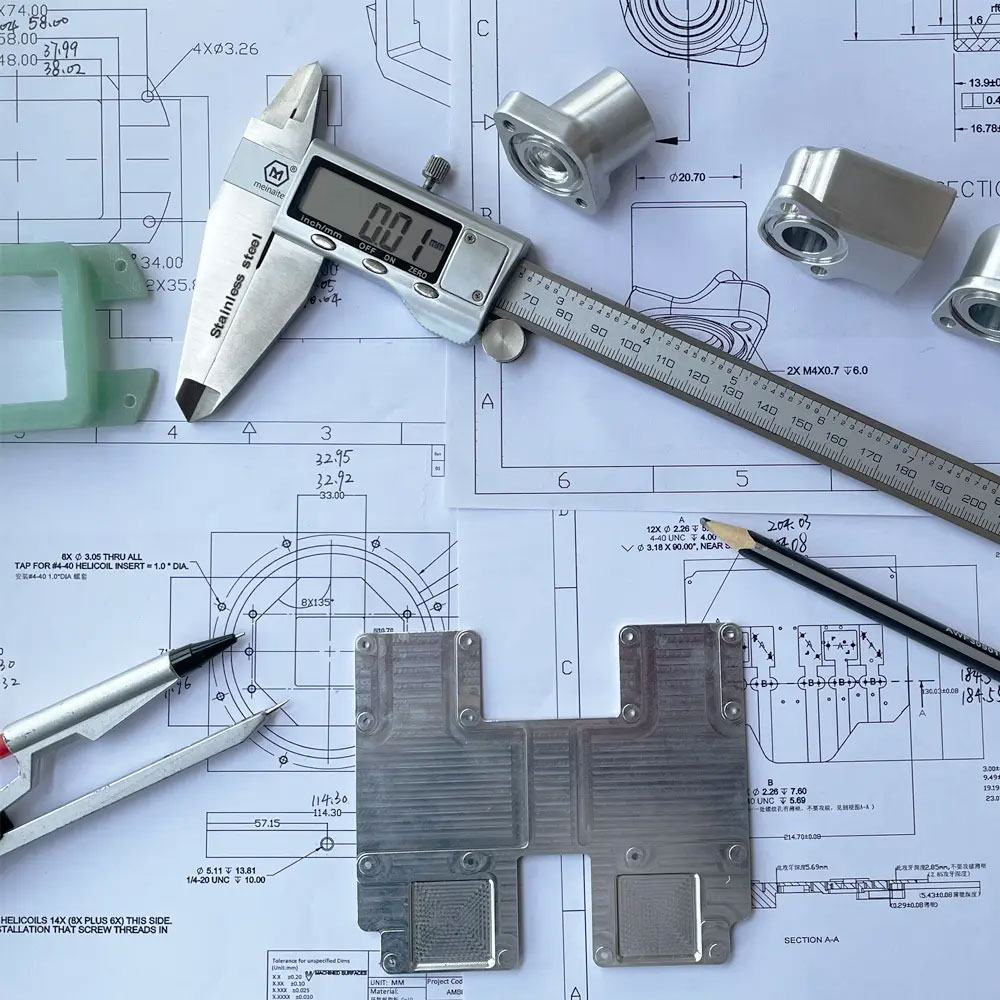

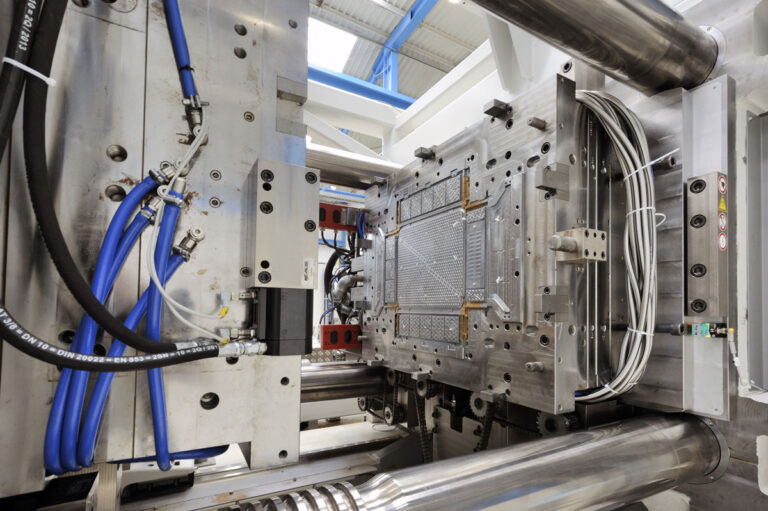

Collect manufacturing information: Collect information related to product manufacturing, including materials, processes, equipment, etc.

Conduct manufacturing feasibility assessment: Based on the collected manufacturing information, evaluate the manufacturability of the product and identify potential problems and difficulties.

Develop optimization plans: Based on the evaluation results, develop plans to optimize product design, improve manufacturing processes, etc.

Implement optimization plans: Implement optimization plans into the actual product design and manufacturing process.

Monitoring and Improvement: During product development and production, we continuously monitor the manufacturability performance of the product and make continuous improvements based on feedback.

5.What is the difference between FMEA and DFM?

The purpose of a manufacturability assessment is to identify potential failure points, which is the key focus and crux of Design for Manufacturing (DFM). Many companies typically utilize FMEA (DFMEA during the design phase and PFMEA during the product phase). FMEA can guide design and review processes, but developing a good FMEA is often difficult, requiring extensive experience from designers and extensive database support from the company. Furthermore, FMEA is not intuitive for DFM and its coverage is limited.

6.DFM other description supplement

| Implementation Direction | 1. Designer level: Engineers use interdisciplinary design techniques to design products; 2. Team collaboration level: Manufacturing, production, testing, and even other functional teams get involved in the PLM process early (design phase). |

| Function | [Diagram: A blue square divided into four parts with DFM in the center] 1. Shorten development time 2. Reduce product costs 3. Reduce modification times 4. Improve product quality |

| Implementation Details | 1. Start from the accumulation of designers/engineers’ personal knowledge and skills. Chief designers should possess a comprehensive knowledge system across product life cycles and professions, and apply this knowledge practically in design to complete the design as accurately as possible in one go (of course, this is a comprehensive measure of results). 2. Team collaboration: – In the later stages of the product PLM process, teams should get involved early to review and correct designs. For example, the mold manufacturing team provides a manufacturability report, and the process team provides an assembly DFM report, etc. |

| Design Techniques | (1) Reduce the number of parts (KISS principle – Keep it simple, stupid). (2) Introduce CAE software analysis in a timely manner during the DVT design phase to guide design corrections. (3) Modular design concept, preferably forming one’s own standardized modules. (4) Avoid over-design (the best way to save costs). (5) Use standard parts and existing raw materials on the market as much as possible. (6) When designing the overall product, consider assembly processes, procedures, and techniques. If in doubt, communicate with the production department in a timely manner. (7) Under the premise of meeting functionality, adopt loose tolerance requirements as much as possible and conduct tolerance analysis on key components. (8) Strictly follow the design Check List for guidance. (Individuals may make mistakes, but documents should not.) |