What is Ultrasonic Machining?

Have you heard of ultrasonic machining? Also known as ultrasonic vibration machining, it is a manufacturing process that removes workpiece material by utilizing high-frequency vibrations combined with particles.

Ultrasonic tools by their very nature create many tiny vibrations that over time remove material from the workpiece it is being used on.

Ultrasonic machining is a subtractive manufacturing process that removes material from the surface of a part by vibrating the tool at high frequency and low amplitude in the presence of fine abrasive particles.

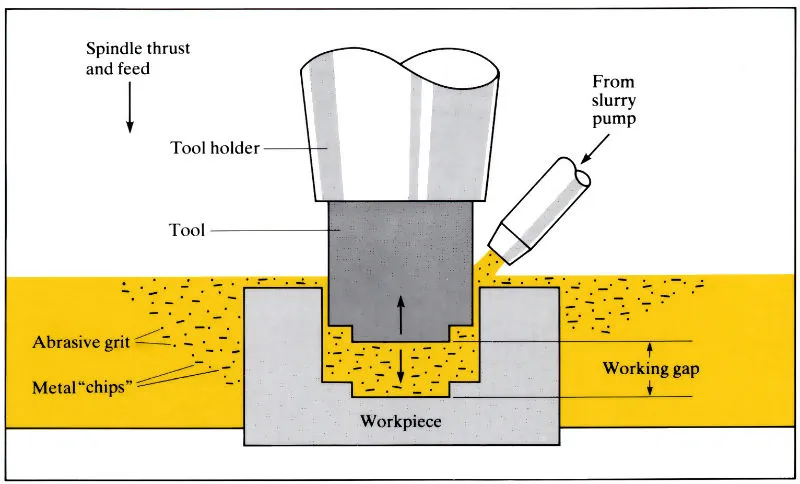

The tool moves perpendicular or normal to the part surface with an amplitude of 0.05 to 0.125 mm (0.002 to 0.005 in.).

Fine abrasive particles are mixed with water to form a slurry that is distributed between the part and the tip of the tool. Typical grit sizes for abrasive particles range from 100 to 1000, with smaller particles (higher grit numbers) producing a smoother surface finish.

Ultrasonic vibration machining is often used for brittle materials as well as materials with higher hardness due to its microscopic crack mechanism.

In ultrasonic machining, the tool generates vibrations that project microscopic particles onto the workpiece. The particles are usually mixed with water or other liquids to form a slurry.

When the ultrasonic tool is activated, it projects these particles at the surface of the workpiece at extremely high speeds. The abrasive nature of the particles helps to remove material from the surface of the workpiece.

Process

The tool used in the machine to cut the material is made of a softer material than the workpiece. Tools are often made of materials such as mild steel and nickel. As the tool vibrates, an abrasive slurry (liquid) containing abrasive particles and grains is added.

The abrasive slurry is added until the workpiece interacts with the particles. Due to the addition of liquid particles, the brittleness of the workpiece causes the workpiece surface to wear away, while the tool gradually deforms.

How it works

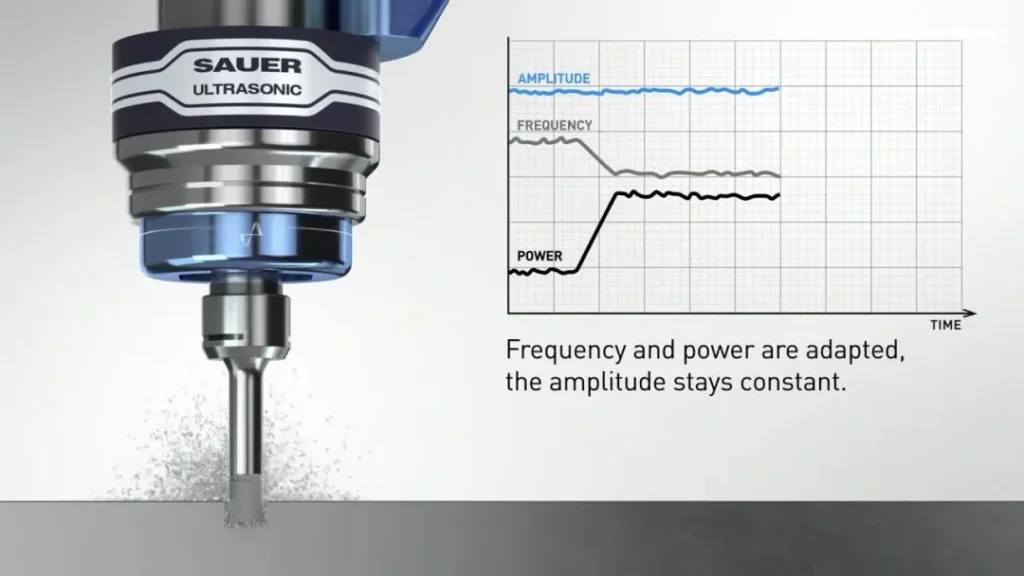

The time spent on the ultrasonic machine depends entirely on the frequency of the vibrating tool. It also depends on the size, stiffness and viscosity of the particles in the abrasive slurry.

The particles used in abrasive fluids are usually boron carbide or silicon carbide because they are harder than other materials. If the viscosity of the slurry is low, the used abrasive can be carried away more easily.

Applications of Ultrasonic Machining

Applications of ultrasonic machining include:

Machining of parts with very high precision and complex shapes.

Drill circular holes of any shape.

Grinding of brittle materials.

Reshape the hole.

engraving.

Circumcision and stamping.

Thread processing.

Cutting and broaching of hard materials.

Processing of glass and ceramics.

Processing precision ores, tungsten, etc.

Mould making and separation operations.

Precise enough to be used in manufacturing MEMS components, such as microstructured glass wafers.

Cut the diamond to get the desired shape.

Advantages of ultrasonic machining

There are many other manufacturing processes that are capable of removing material from a workpiece, but their application is generally limited to workpieces made of strong, durable materials.

However, ultrasonic machining is unique in that it is capable of removing material from nearly all types of workpieces, including those made from hard and brittle materials.

Whether a workpiece is made of glass, ceramic or quartz, ultrasonic machining can be used to change its physical dimensions.

Ultrasonic machining does not require heating of the workpiece. If the workpiece is sensitive to thermal fluctuations, it can be safely altered using this machining process. During ultrasonic machining, the temperature of the workpiece will remain constant. In other words, the process requires neither heating nor cooling of the workpiece.

In addition, ultrasonic machining has higher tolerances than many other machining processes. It is able to alter the workpiece with high tolerances that cannot be achieved with other machining processes.

Disadvantages of Ultrasonic Machining

On the other hand, ultrasonic machining also has some disadvantages, one of which is that the material removal rate is slower than average. It is not a particularly fast method of removing workpiece material.

On the contrary, it is slower than most other machining processes.

In addition to slower than average material removal rates, ultrasonic machining does not allow for deep holes.