Short Intro

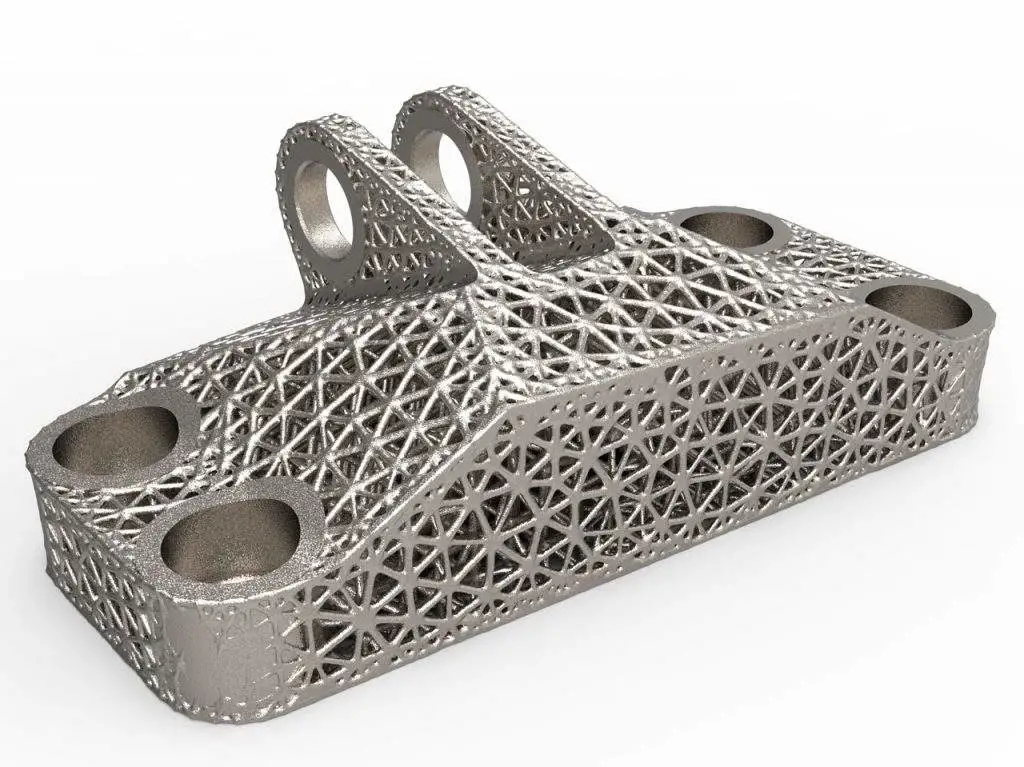

One of the most impressive features of 3D printing is its ability to create parts with complex internal lattice structures that are impossible using traditional manufacturing techniques.

Designing a part around a lattice reduces its overall mass without significantly affecting its overall strength.

What is the lattice structure of 3D printing?

Simply put, a 3D printed lattice structure is a repeating or non-repeating 3D collection of connected nodes. In its simplest form, multiple lattice nodes are connected to each other by beams.

In the case of repeating 3D structures, the collection of beams and nodes takes regular and repeating 3D shapes such as cubes or tetrahedrons, which are often referred to as unit cells.

The shape and density of these elements will determine how the part behaves when loads are applied.

3D printed lattice structures make optimal use of the unique capabilities of the material and printer by placing mass only where it is structurally needed.

As a result, the overall project can be much lighter than a completely solid one. This is one reason why lattice structures are so common in nature.

Benefits of lattice structure

Lattice structures for 3D printing offer a wide range of benefits. Some of the most important are listed below.

1.Reduce parts costs:

Depending on the material, 3D printing can be an expensive process. This is especially true for materials like titanium or Inconel, which are common in the aerospace industry. The introduction of a lattice structure means less material is used, making the part cheaper overall without sacrificing structural integrity.

2.Improved strength-to-weight ratio:

Parts with lattice structures can have unparalleled strength-to-weight ratios if designed according to recognized DFAM (Design for Additive Manufacturing) principles.

This makes it ideal for automotive and aerospace applications (among others) where minimizing mass is critical.

3. Shock absorption:

Lattice structures are very effective at dissipating shock and impact loads because the cell structure aids in bending and energy distribution throughout the structure.

4. Increase surface area:

Some applications focus on maximizing surface area rather than mechanical strength. For example, heat transfer or chemical reactions may be the primary goal. Lattice structures are useful here because they provide a part with more surface area without increasing its overall footprint.

5. Osseointegration:

This refers to a method of creating a lattice structure within medical implants to promote bone growth. The resulting implant forms a stronger bond with the patient’s own bone structure.

Summary

Generally speaking, 3D-printed lattice structures can help engineers to push the limits of materials science while reducing overall part mass.

Lattice structures have only recently begun to move from advanced aerospace applications to more common consumer products, thanks to the growing popularity of 3D printers and decreasing material costs.

This design style has persisted simply because the lattice is so efficient.