Introduction

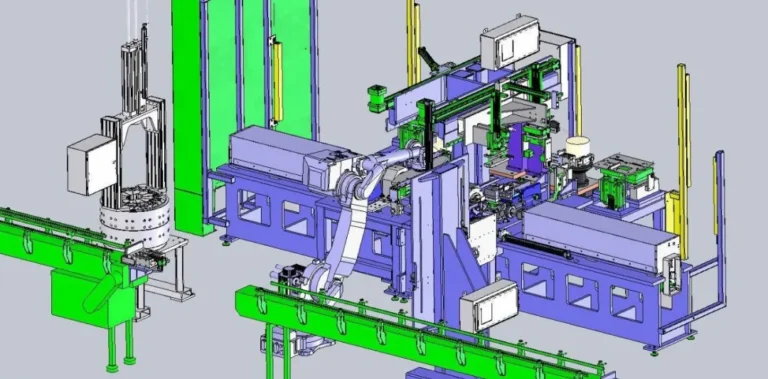

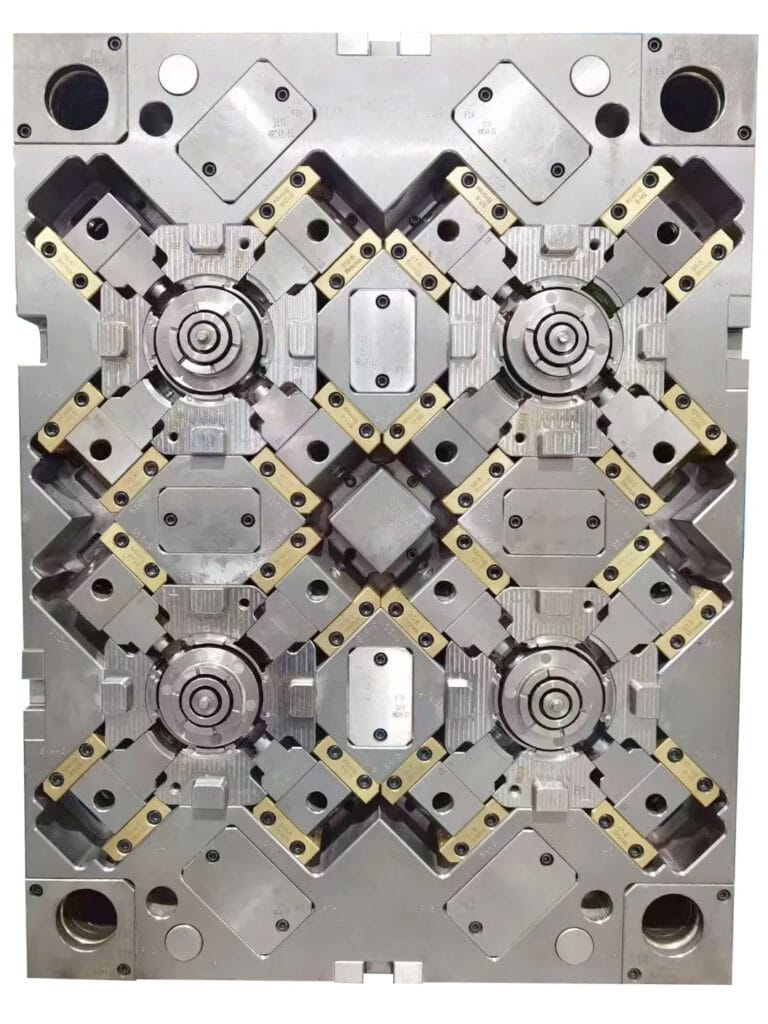

Molds are a mainstream and conventional manufacturing technology for the industry. Rapid molds, as the name implies, are molds that take a short time to produce, more than 1.5 times faster than conventional mold production. They are all molds, so why are rapid molds so fast? Gaofeng Prototyping has all the experience in manufacturing various rapid molds. While meeting product requirements, we simplify the mold processing and manufacturing process. For example, our rapid molds have mold frames of different sizes in stock, so that the mold frames can be shared, and there will be no duplication of production and processing work, and only fine-tuning is required.

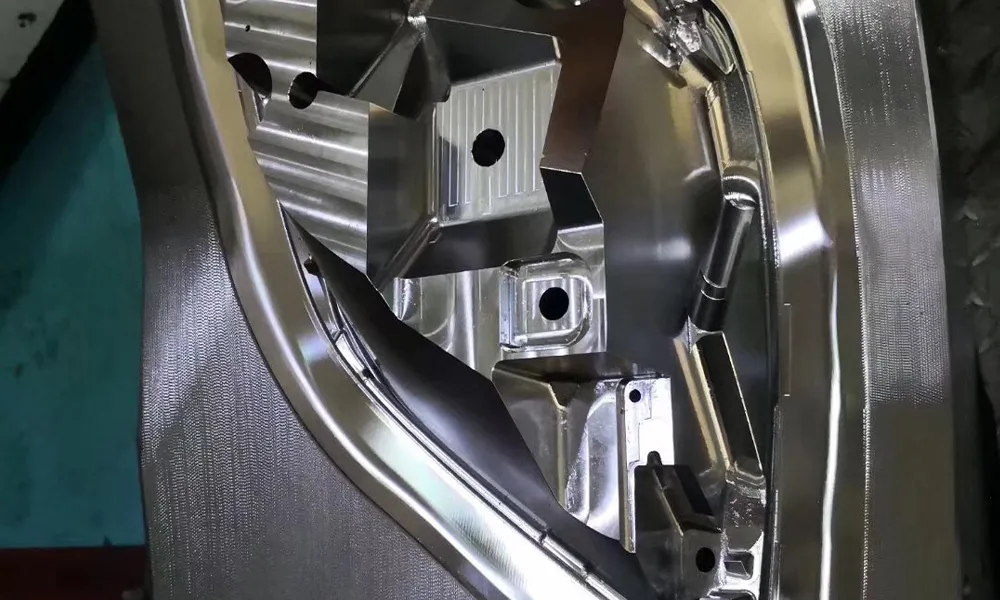

Our rapid molds rarely use automatic inserts and sliders, and are basically operated manually. Rapid mold customers do not have high requirements for mass production. When the output is not high, it will be better to replace intelligent automation with manual labor. Of course, rapid molds have more quick tricks and details during manufacturing, and there will be more detailed process decomposition for customer drawings.

What Is Rapid Tooling (RT)

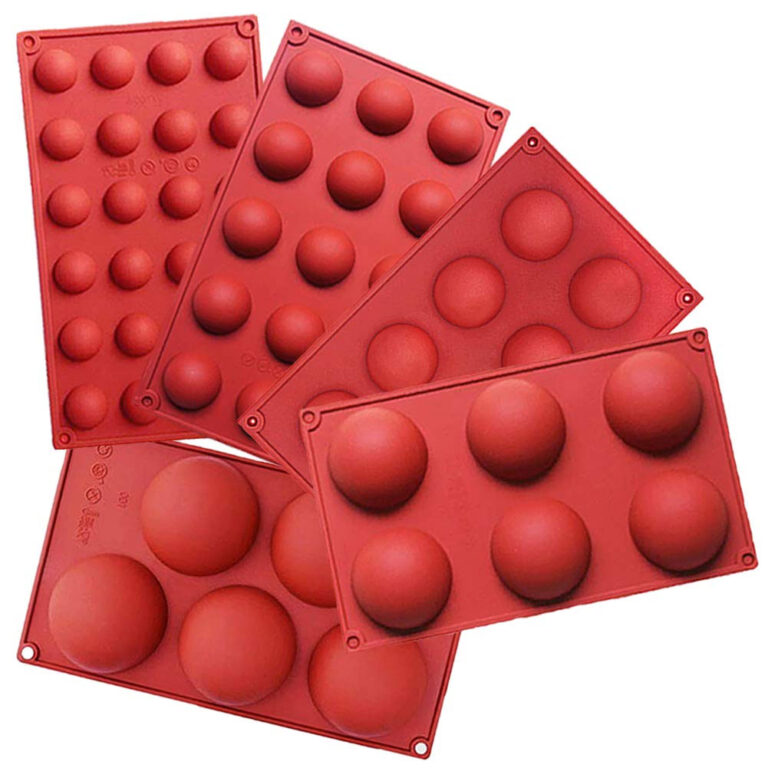

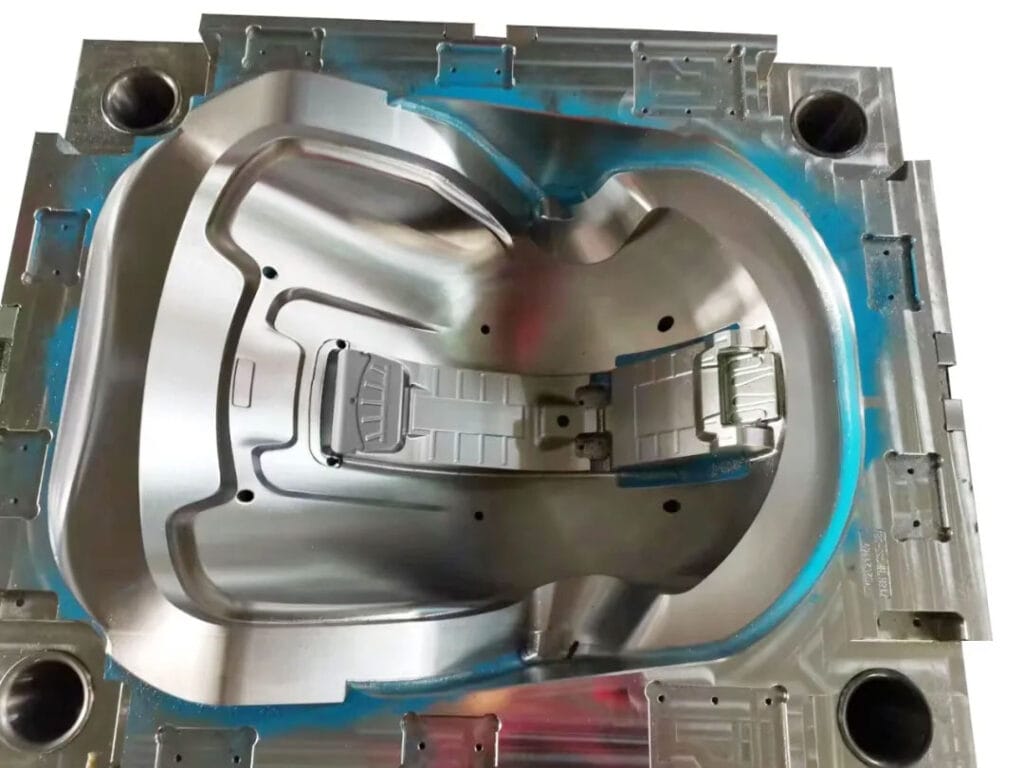

Rapid molds, also known as Simple test molds, are typically used before production of a full-size mold. These molds can reduce the amount of modification work required for the full-size mold, quickly identify structural issues, and extend the production life of the full-size mold. They offer low production costs, fast turnaround times, and a short development cycle.

The scope of molds is wide and involves a wide range of industries. Molds can be called the mother of industrial manufacturing. It can even be said that there would be no new products without molds. Today we will talk about the rapid steel mold within the mold range, also known as the soft mold.

Rapid steel mold itself is not the mainstream in industrial manufacturing process. Many manufacturing professionals are not very clear about what rapid mold is and its purpose. The industry calls it differently, such as rapid mold, rapid soft mold, rapid steel mold, rapid aluminum mold, etc. Although they are called differently, the requirements are similar, that is, “fast”.

Advantages of rapid aluminum mold:

- Aluminum mold shape is easy to modify (aluminum has good plasticity and processing properties)

- Fast processing time (aluminum processing is fast)

- Aluminum materials are available for ordering (order today and it will arrive for processing tomorrow)

- The mold can be textured and polished

Disadvantages of rapid aluminum molds:

- The mold life is between 1K-1W

- Mold injection production is not subject to pressure

What role does rapid prototyping play?

Rapid molds are generally used in the R&D trial production stage, and are also used in the production of various products with low output. Rapid molds are sometimes also called test molds. Before mass production of products, a set of rapid molds are made for experiments and engineering structure verification before the formal mold is produced. Rapid molds have low costs, short production time, and can promptly discover its irrationality before the formal mold is produced, allowing engineering R&D personnel to intuitively see the problems on the rapid mold, and then modify the mold product drawings to extend the service life of the formal mold.

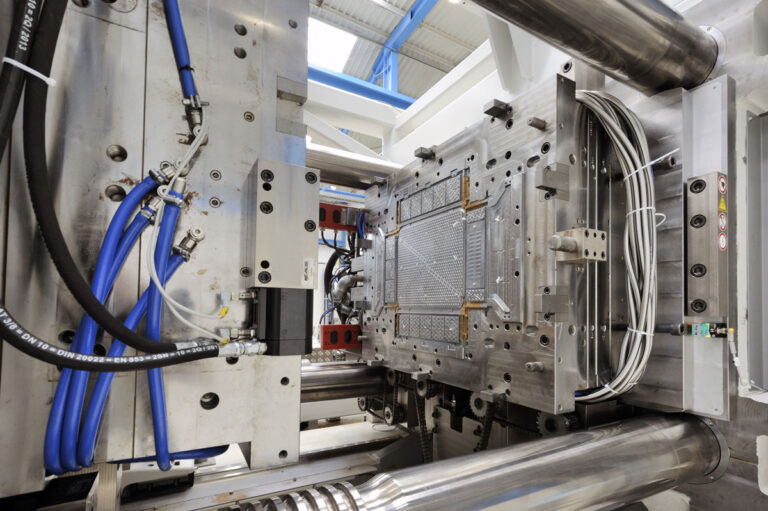

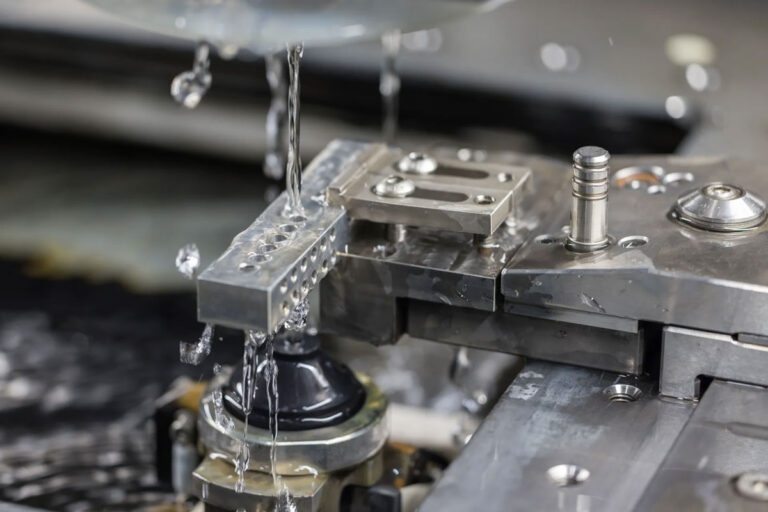

Materials used in rapid molds

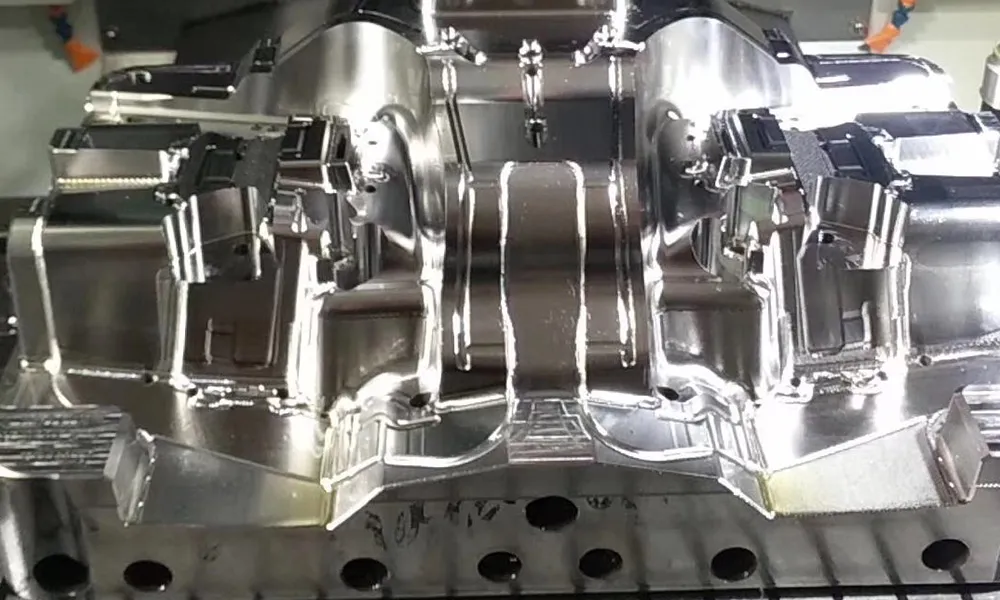

Rapid molds are typically made of P20 aluminum alloy or 45# steel, formed through sand casting, forging, or CNC machining of extruded steel and aluminum sheets. Auxiliary machining processes such as wire cutting, sparking, and wire-cutting are combined to quickly create a simple test mold. The product is then produced using plastic injection molding.

Rapid mold processing cycle

The entire molding cycle for a rapid mold can be completed in as little as three days, or as slowly as seven days for a simple mold. For particularly large products, such as automotive front bumpers, a quick and simple mold can be produced within 30-40 days. For smaller 3C products, such as chargers, a quick and simple mold can be completed in as little as seven days.

Tips for Rapid Molds

The rapid tooling process streamlines production, simplifying all possible processing methods for the full-scale mold. The mold shares a common mold frame and lacks a core, eliminating the need for fully automated pin extraction, sliders, inserts, and manual removal and injection molding required for the full-scale mold. Products with partial internal and tilting tops typically undergo secondary machining to improve the product structure. Since production volumes for rapid molds are generally low, a simple, time-saving, and cost-effective method is used to quickly complete the simple mold process.

What kind of products are suitable for rapid molds?

Plastic parts with production batches of less than 5,000 are very suitable for rapid tooling. The mold cost is low, the production time is short, and the change is fast. The speed of product appearance change in the new era is unimaginable. For example, some products such as mobile phones and automobiles are put on the shelves not long after consumers buy them. In the era of rapid changes in consumer categories, rapid tooling plays a big role.