When injection molding PFA (fluoroethylene propylene, a fluoroplastic), special attention should be paid to its high-temperature processability, poor fluidity, and easy decomposition. The following is a detailed description of the key considerations:

1.Material pretreatment

- Low hygroscopicity but requires cleaning:

- PFA has very low hygroscopicity (water absorption rate <0.01%) and usually does not require drying, but storage contamination (especially dust) must be avoided.

- If the material is exposed to a humid environment, it can be dried for a short time (80-100℃, 1-2 hours).

- Material purity requirements:

- For semiconductor and medical grade applications, high-purity grades (such as Chemours Teflon® PFA) should be selected to avoid the introduction of impurities.

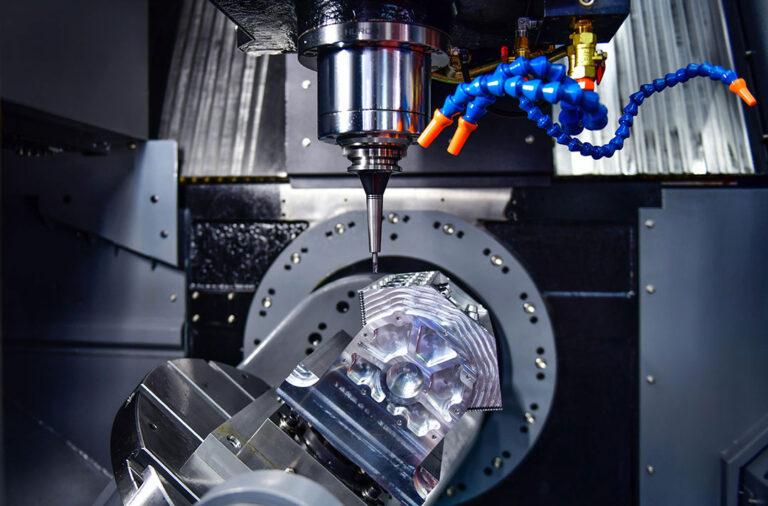

2.Injection molding machine selection

- High temperature and corrosion resistant configuration:

- The barrel and screw must be resistant to high temperatures (above 400°C) and resistant to fluoroplastic corrosion (chrome-plated screw or double alloy screw is recommended).

- Screw design: aspect ratio ≥ 20:1, compression ratio 2.5-3.0, to avoid shear overheating.

- Clamping force requirement: calculated based on the projected area of the product (usually 400-600 tons/m²).

- Nozzle and flow channel:

- Use an open nozzle to avoid dead corners; the flow channel should be short and thick (diameter ≥ 8mm) to reduce melt retention.

3.Process parameter optimization

- Temperature control:

- Barrel temperature: set in sections, rear section (feeding area) 300-330℃, middle section 340-370℃, front section 380-410℃.

- Nozzle temperature: slightly lower than the previous section (380-400°C) to prevent drooling.

- Mould temperature: 150-200℃ (high temperature mould can improve fluidity and reduce weld marks).

- Injection parameters:

- Injection speed: medium to low (avoid high shear speed that causes decomposition).

- Injection pressure: 60-100 MPa (high pressure is required for thin-walled parts and lower pressure is appropriate for thick-walled parts).

- Holding pressure: 40-60% of the injection pressure, the holding time needs to be long (cooling shrinkage rate 1.5-3%).

- Cooling time: long (about wall thickness × 30-40 seconds/mm) to ensure sufficient cooling and shaping.

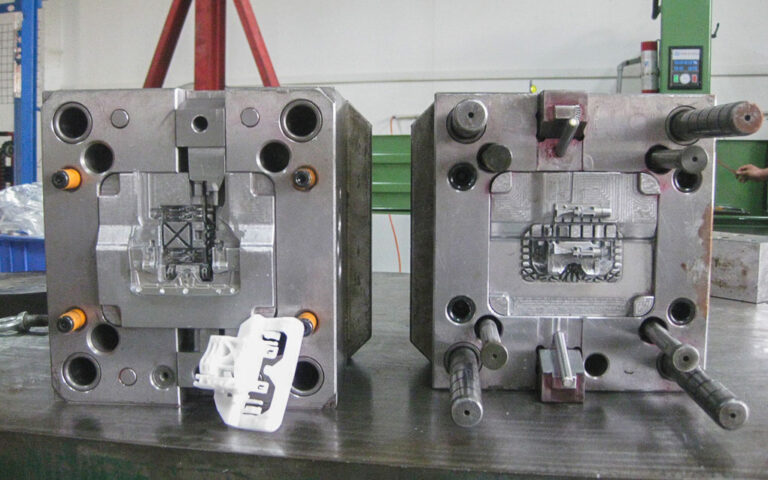

4.Key points of mold design

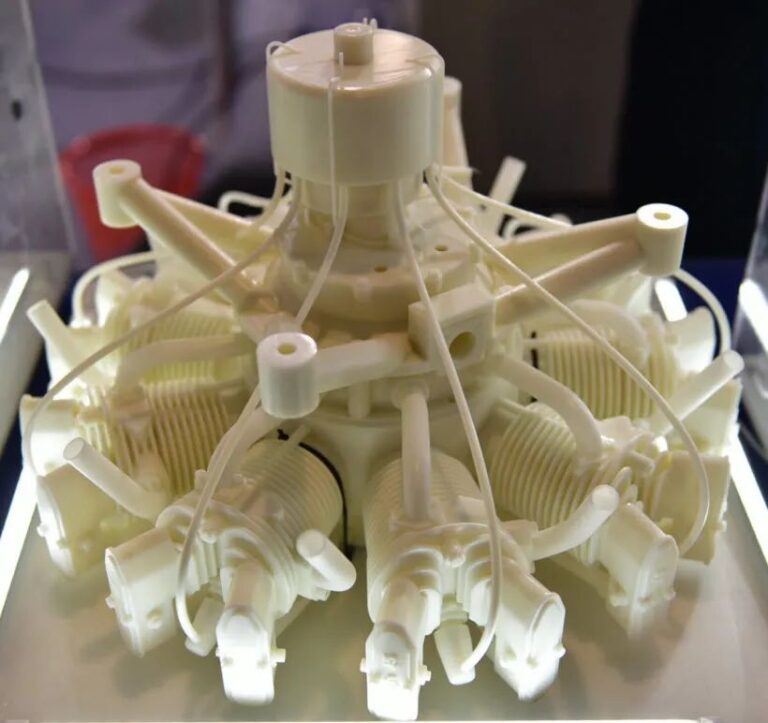

- Runner and gate:

- Hot runner is preferred (to reduce cold material residue), and the cold runner needs to be heated to above 200℃.

- Gate type: large fan gate or direct gate, avoid point gate (which can easily cause shear decomposition).

- Exhaust design:

- The depth of the venting groove is 0.03-0.05mm (PFA melt has high viscosity and requires sufficient venting).

- Add exhaust inserts to the parting surface to prevent trapped air from burning (decomposition will release toxic gases).

- Surface treatment:

- The mold surface is hard chrome plated or nitrided to reduce mold sticking.

- Demolding angle ≥ 2° (PFA has a large shrinkage rate and is prone to mold sticking).

5.Post-processing and quality control

- Annealing (optional):

- If the product has internal stress, it can be annealed at 200-230℃ for 1-2 hours and cooled slowly.

- Key points of testing:

- Visual inspection: Observe for yellowing or black spots (signs of decomposition).

- Performance testing: dielectric strength, chemical resistance (such as ASTM D3307 standard).

- Purity testing: Semiconductor-grade PFA must pass ionic contamination testing (such as ICP-MS analysis).

6.Common Problems and Solutions

- Material breakdown:

- Symptoms: The product turns yellow and has a pungent odor.

- Countermeasures: Lower the barrel temperature (especially in the front section <410°C) and shorten the melt residence time (<5 minutes).

- Sticking mold:

- Increase the mold temperature to the upper limit (200°C) and use a PTFE-based release agent (must comply with FDA or USP Class VI certification).

- Bubbles or voids:

- Check whether the mold is adequately vented and increase the holding pressure and time.

7.Safety and Environmental Protection

- Decomposition of risks:

- PFA decomposes at high temperatures and releases toxic gases such as hydrogen fluoride (HF), so a powerful exhaust system is required.

- Operators must wear gas masks and high-temperature resistant gloves.

- Waste disposal:

- Waste materials cannot be incinerated directly and must be handed over to professional fluoroplastic recycling agencies for disposal.

8.Application scenario adaptation

- High-purity fields (semiconductors, pharmaceuticals):

- Choose a low-precipitation grade (such as Daikin Neoflon® PFA). The mold needs to be electropolished (Ra ≤ 0.1μm).

- Corrosion-resistant components:

- Must pass ASTM G154 UV aging test to ensure long-term acid and alkali resistance.

By strictly controlling processing temperature, mold design, and process parameters, decomposition and defects in PFA injection molding can be effectively avoided. It is recommended to optimize parameters through trial molds and regularly clean the injection molding machine of residues (PFA is prone to carbonization and adhesion).