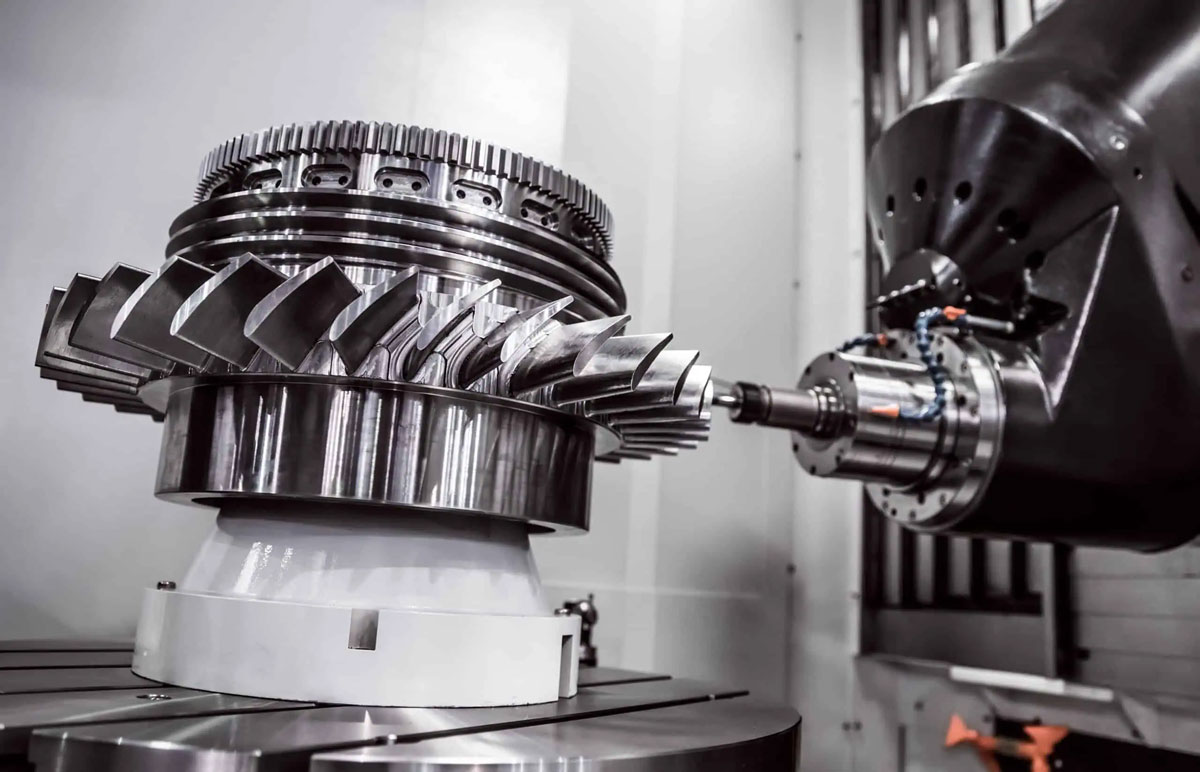

What Is Machining accuracy?

Machining accuracy is the degree to which the actual size, shape, and position of the machined part surface conform to the ideal geometric parameters specified in the drawing! Ideal geometric parameters, for size, are average dimensions; for shape, they are absolute circles, cylinders, planes, cones, and straight lines; and for relative positions, they are absolute parallelism, perpendicularity, coaxiality, and symmetry.

1.Dimensional accuracy

The degree of conformity between the actual size of the part after processing and the center of the tolerance zone of the part size.

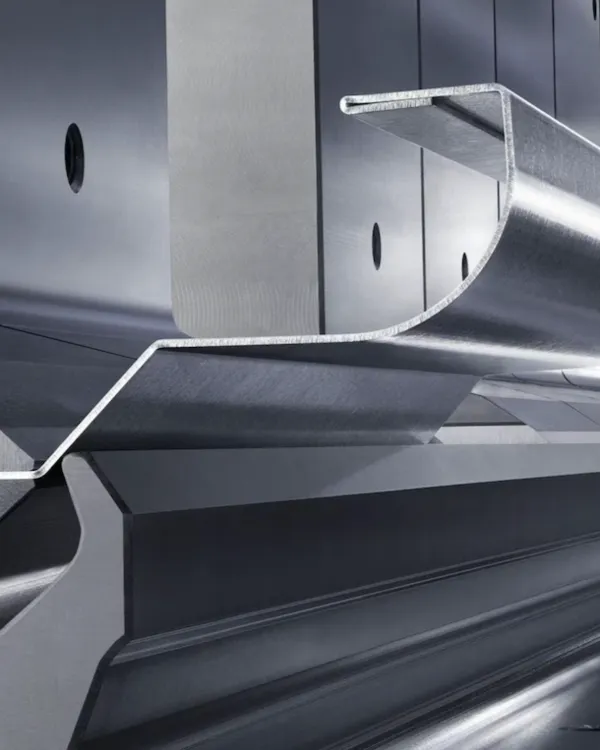

2.Shape accuracy

Refers to the degree of conformity between the actual geometric shape of the surface of the machined part and the ideal geometric shape.

3.Position accuracy

Refers to the actual position accuracy difference between the relevant surfaces of the parts after processing.

When designing machine parts and specifying their machining accuracy, care should be taken to keep form errors within position tolerances, which in turn should be smaller than dimensional tolerances. This means that for precision parts or critical surfaces, form accuracy requirements should be higher than position accuracy requirements, which in turn should be higher than dimensional accuracy requirements.

The deviation between the actual and ideal geometric parameters of a part is called machining error . The magnitude of the machining error reflects the level of machining accuracy. The larger the error, the lower the machining accuracy, while the smaller the error, the higher the machining accuracy.

Introduction to machining accuracy

Machining accuracy is primarily used to measure the degree of product quality . Both machining accuracy and machining error are terms used to evaluate the geometric parameters of a machined surface . Machining accuracy is measured by tolerance grade; smaller grades indicate higher accuracy. Machining error is expressed numerically; larger values indicate greater error. High machining accuracy translates to low machining error, and vice versa.

There are 20 tolerance grades ranging from IT01, IT0, IT1, IT2, IT3 to IT18. Among them, IT01 indicates that the part has the highest processing accuracy, and IT18 indicates that the part has the lowest processing accuracy. Generally, IT7 and IT8 are medium levels of processing accuracy.

The actual parameters obtained by any processing method will not be absolutely accurate. From the perspective of the function of the part, as long as the processing error is within the tolerance range required by the part drawing, the processing accuracy is considered to be guaranteed.

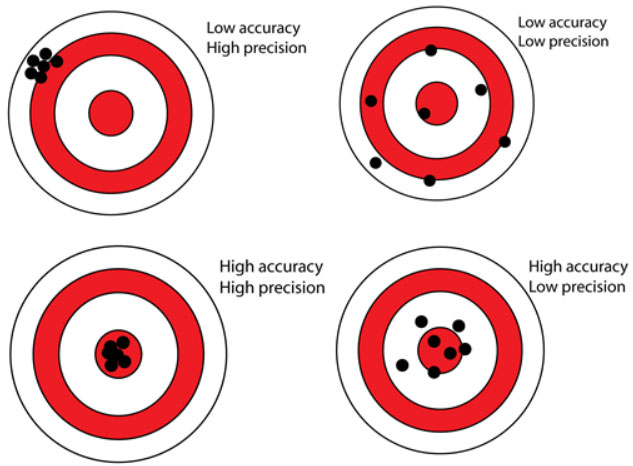

The difference between accuracy and precision:

1.Accuracy

Refers to the degree of closeness between the measurement result and the true value . High measurement accuracy means that the systematic error is small, and the average value of the measured data deviates little from the true value, but the data is scattered, that is, the size of the random error is unclear.

2.Precision

This refers to the reproducibility and consistency of results obtained from repeated measurements using the same spare sample . It’s possible to have high precision but inaccurate accuracy. For example, if three measurements using a 1mm length yielded results of 1.051mm, 1.053mm, and 1.052mm, respectively, while having high precision, they are inaccurate.

Accuracy indicates the correctness of the measurement results, and precision indicates the repeatability and reproducibility of the measurement results. Precision is a prerequisite for accuracy.

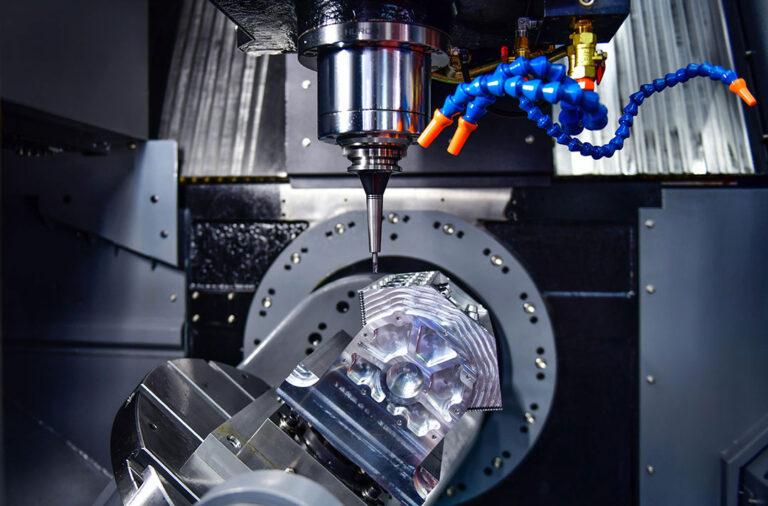

Methods to improve machining accuracy

1. Adjust the process system

1) Trial cutting method adjustment

The process is repeated through trial cutting, measuring the size, adjusting the tool engagement, cutting, and trial cutting until the required size is achieved. This method has low production efficiency and is mainly used for single-piece and small-batch production.

2) Adjustment method

The required dimensions are achieved by pre-adjusting the relative positions of the machine tool, fixture, workpiece, and tool. This method has high productivity and is mainly used for large-scale mass production.

2. Reduce machine tool errors

1) Improve the manufacturing accuracy of spindle components

The rotation accuracy of the bearing should be improved:

①Select high-precision rolling bearings;

②Use high-precision multi-oil wedge dynamic pressure bearings;

③Use high-precision hydrostatic bearings,

The precision of bearing accessories should be improved:

① Improve the machining accuracy of the box support hole and the spindle journal;

② Improve the machining accuracy of the surface matching the bearing;

③Measure and adjust the radial runout range of the corresponding parts to compensate or offset the errors.

2) Properly preload the rolling bearing

①Can eliminate gaps;

②Increase bearing stiffness;

③Equalize rolling element errors.

3. Reduce transmission chain transmission error

1) Fewer transmission parts, shorter transmission chain and higher transmission accuracy;

2) Using reduced speed transmission is an important principle to ensure transmission accuracy, and the closer the transmission pair is to the end, the smaller its transmission ratio should be;

3) The precision of the end piece should be higher than that of other transmission parts.

4. Reduce tool wear

The tool must be re-sharpened before the dimensional wear reaches the stage of rapid wear