Intro

Parametric modeling volume is not moving?

“It’s not because you can’t design, it’s that the design tools are eliminating you.”

In the past 10 years, industrial design, molds, architecture, and product modeling have almost defaulted to using parametric modeling tools such as SolidWorks, UG, and Inventor.

But now, more and more companies and designers are quietly turning to Rhino.

This is not a coincidence in the tool trend, but a trend shift driven by “changes in demand”.

Why is “parametric modeling”losing its leading position?

It doesn’t mean that parametric modeling is bad. Tools such as SolidWorks, UG, and Inventor should still be used.

But many designs can no longer be accomplished by a single straight line or a set of dimensions.

The projects that really make money are becoming less and less “rules”:

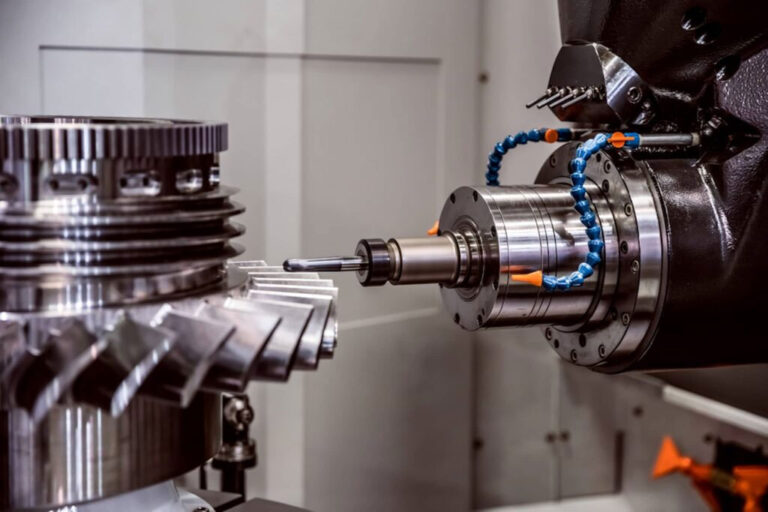

Complex molds: free draft, undercuts, and surface interference are everywhere

Medical Scan: STL model is severely damaged and cannot be parameterized

Consumer electronics: Industrial design emphasizes “sensory styling” rather than structural puzzles

Architectural expression: Special-shaped shells and hyperbolic curtain walls are difficult to draw using traditional logic

The result is: “Drawings are always being revised and software is always crashing.”

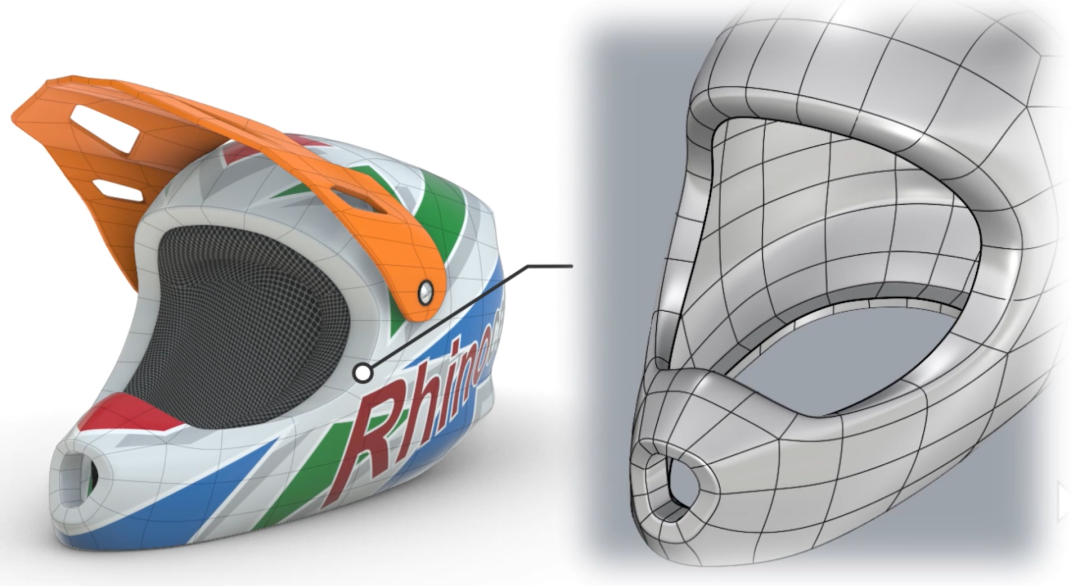

Rhino is designed for these “unbuildable models”

Many people misunderstand that Rhino is only used for drawing shells. In fact, its core capability is to transform “non-parameterizable” surface structures into “manufacturable models.”

Unlike traditional CAD which requires sketching layer by layer, Rhino usually allows you to work directly on the surface.

you can:

Pull a section of the scanned mesh to form a solid model;

Generate a continuous smooth free surface using several curves;

Make detailed adjustments directly without destroying the structure;

Quickly repair, split, and build a solid from an STL file that originally had no parameters.

Let’s take a look at it intuitively through the comparison of the following table:

| Modeling method | Traditional CAD | Rhino |

|---|---|---|

| Thinking Logic | “Size → Structure → Processing” | “Modeling → Surface → Output” |

| Core Tools | Sketch, extrude, hole, pattern | Curve, surface, and mesh operations |

| Modeling direction | Clear structure and processing-friendly | Free styling, stronger expression |

| Application Areas | Machinery, assembly, product structure | Industrial design, architecture, mold, reverse engineering |

It is not that Rhino replaces CAD, but Rhino fills in the gaps that CAD cannot cover.

Typical Application Scenarios

Many Rhino uses are actually forced by projects:

- Medical companies make custom implants and can only use scan data to restore → Rhino

- The mold factory receives a reverse part from the customer who only provided STL → Rhino

- An architect is trying to draw a hyperbolic curtain wall, but Revit can’t do it → Rhino + Grasshopper

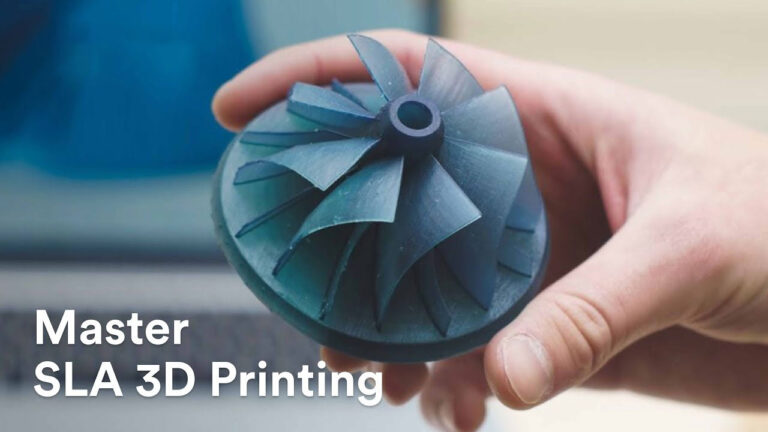

- Consumer electronics products need to quickly verify the appearance + prototype printing → Rhino processing STL

Rhino opens another door to modeling

Rhino may not be for everyone, but if you:

- I am always frustrated by strange-looking models.

- Often need to process STL, scan data, non-standard shapes

- Want to understand how those beautiful but “irregular” shapes are built

- Don’t want to be trapped by the feature tree “blowing up half an hour of work” anymore

Then you should really take a look at Rhino. It’s not about catching up with the trend, but about catching up with the tool that is just right for you.

Conclusion

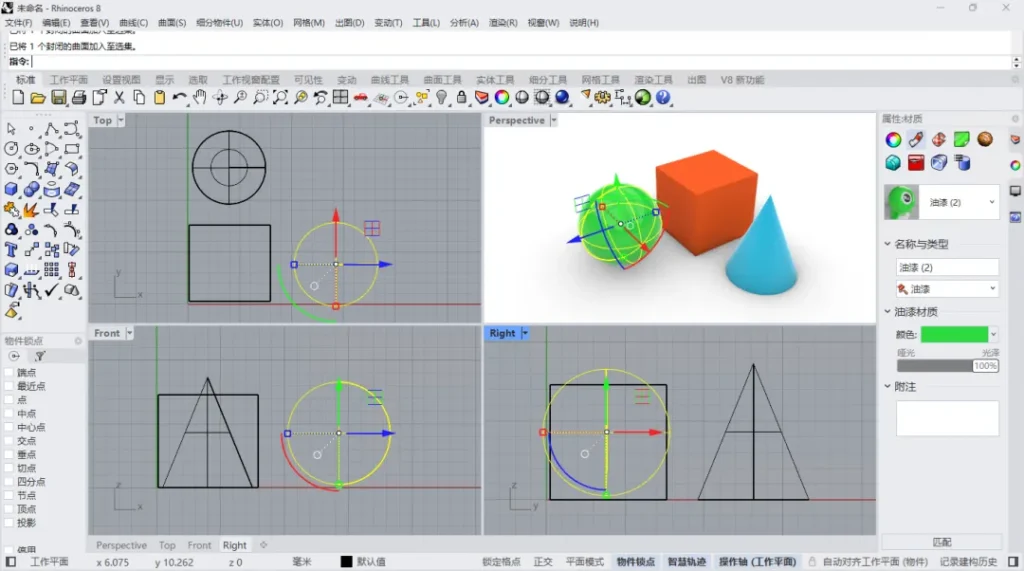

Rhino is a powerful 3D NURBS modeling software that supports both Windows and macOS platforms. It has extremely high precision and good compatibility and is widely used in architecture, industrial design, jewelry design and other fields.

Rhino can create, edit, analyze, document, render, animate, and convert NURBS curves, surfaces, solids, subdivision geometry (SubD), parametric generation (Grasshopper), point clouds, and polygonal meshes. It also supports exporting to various 3D formats for other software and supports third-party plug-ins. As long as the hardware allows, there are no restrictions on complexity, order, or size.

From simple geometric shapes to complex curves and surfaces, Rhino can handle it.

Official website: https://rhino3d.com