Production workshop

The layout of the production workshop focuses on two aspects: meeting production demand conditions, optimizing the layout according to the production process, and meeting the requirements of flexible energy use under specific production conditions.

- The power supply should meet the power requirements for stable production while having an appropriate margin, so as not to cause excessive power consumption due to excessive surplus.

- Build efficient cooling water circulation facilities and equip the cooling water system with an effective insulation and thermal insulation system.

- Optimize the overall production layout of the workshop. Many production processes require coordination of sequential steps. Proper coordination can reduce turnover time and energy consumption, thereby improving production efficiency.

- For lighting and other factory equipment, consider controlling them separately in the most effective small units.

- Carry out regular maintenance of workshop equipment to avoid damage to public facilities, which may affect normal production operations and increase energy consumption.

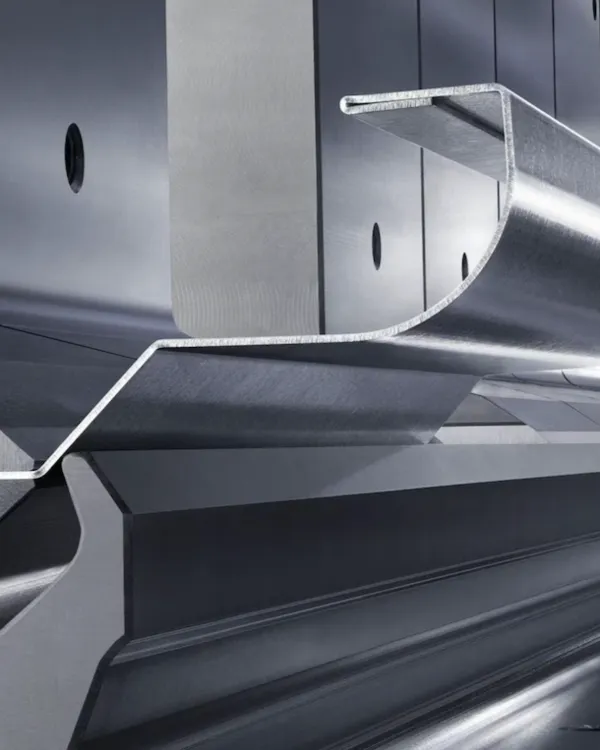

Injection molding machine

The injection molding machine is a major energy consumer in the injection molding workshop, and the energy consumption mainly comes from the motor and heating.

- Choose the right injection molding machine based on the product’s characteristics. “Big horse pulling a small cart” injection molding often means a lot of energy waste.

- Use all-electric injection molding machines and hybrid injection molding machines, which have excellent energy-saving effects and can save 20-80% of energy.

- The use of new heating technologies, such as electromagnetic induction heating and infrared heating, can achieve 20-70% heating energy savings.

- Use effective insulation measures for heating and cooling systems to reduce heat and cold losses.

- Keep the transmission parts of the equipment well lubricated to reduce the increase in energy consumption caused by increased friction or unstable equipment operation.

- Use low-compression hydraulic oil to reduce energy waste in the hydraulic system.

- The use of parallel action, multi-cavity injection molding, multi-component injection molding and other processing technologies can significantly save energy.

- Traditional mechanical hydraulic injection molding machines also have a variety of energy-saving drive systems, which replace traditional quantitative pumps and have significant energy-saving effects.

- Regularly maintain the heating and cooling pipes to ensure that there are no impurities, scale blockages, etc. inside the pipes to achieve the designed heating and cooling efficiency.

- Ensure that the injection molding machine is in good working condition. An unstable process may result in defective products and increase energy consumption.

- Ensure that the equipment used is suitable for the product being processed. For example, PVC processing often requires a special screw.

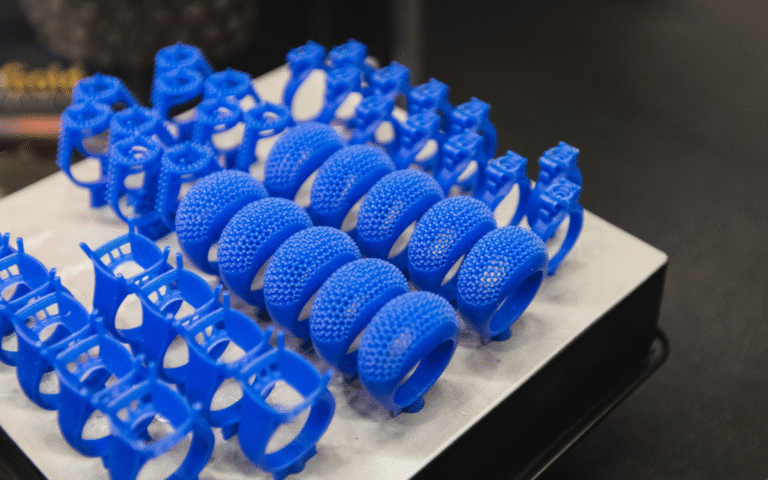

Injection mold

Mold structure and mold condition often have a significant impact on injection molding cycle and processing energy consumption.

- Reasonable mold design, including runner design, gate form, number of cavities, heating and cooling water channels, etc., can help reduce energy consumption.

- The use of hot runner molds can not only save materials and reduce energy consumption in material recycling, but the molding process itself also has a significant energy-saving effect.

- Contour-forming quick cooling and heating molds can significantly save processing energy and achieve better surface quality.

- Ensure balanced filling of each cavity, which helps to shorten the molding cycle, ensure uniform product quality, and have excellent energy-saving effects.

- Using CAE-assisted design technology for mold design, mold flow analysis and simulation can reduce the energy consumption of mold debugging and multiple mold repairs.

- Under the premise of ensuring product quality, using lower clamping force for molding will help extend the life of the mold, facilitate rapid mold filling, and help save energy.

- Perform mold maintenance work to ensure effective heating and cooling water channel conditions.

Peripheral Equipment

- Choose auxiliary equipment that is suitable for your capabilities, so that it can meet the work requirements without being too redundant.

- Perform proper equipment maintenance to ensure it is in normal working condition. Abnormally functioning auxiliary equipment can cause unstable production and even poor part quality, leading to increased energy consumption.

- Optimize the coordination and operation sequence between the host and peripheral devices.

- Optimize the relative positions of peripheral equipment and production equipment, and place peripheral equipment as close to the host as possible without affecting operating conditions.

- Many auxiliary equipment manufacturers provide on-demand energy supply systems, which can achieve significant energy savings.

- Use quick mold change equipment to reduce the waiting time required to switch products during production.

Materials

The energy consumption of processing different materials is different. At the same time, poor material management or improper management of recycled materials will increase production energy consumption.

- Under the premise of meeting the performance of the product, materials with lower processing energy consumption should be given priority.

- Under the conditions of meeting the requirements of performance and cost optimization, high fluidity materials are given priority.

- Note that materials from different suppliers may have different process conditions.

- Dry the material. It is best to use it immediately after drying to avoid wasting energy due to moisture in the material after drying.

- Take good care of material storage to prevent impurities or foreign matter from entering the material, which may eventually lead to defective products.

- Some products are allowed to add a certain amount of recycled materials, but attention should be paid to the storage and cleanliness of the recycled materials to avoid defective parts due to unclean materials.

Processing technology

- Use the shortest molding cycle while meeting product performance requirements.

- If there are no special factors affecting the process, try to use the processing technology recommended by the supplier.

- For specific products and molds, all stable equipment and process parameters are saved to shorten the machine adjustment time when changing production next time.

- Optimize the process and adopt lower clamping force, shorter cooling time and holding time.

Adopting new technologies

- Use auxiliary molding technology, such as gas-assisted, liquid-assisted, steam-assisted, micro-foaming injection molding technology, etc.

- Adopt unitized molding solution to reduce intermediate links.

- Adopt new technologies such as in-mold welding, in-mold spraying, in-mold assembly, and in-mold decoration.

- Adopt the new low-pressure molding technology to shorten the molding cycle and reduce the melt temperature.

- Use energy regeneration system.

Production Management

- Producing high-quality products in one go and reducing the defective rate is the greatest energy saving.

- Maintenance of the entire production system is closely related to energy consumption. This affects not only the main machine, but also peripheral and factory equipment. For example, if a mold-changing crane breaks down in the workshop, manual labor is required to change the mold, which inevitably increases equipment waiting time and energy consumption.

- Equipped with a workshop energy consumption monitoring system to facilitate the company’s targeted implementation of energy analysis and improvement.

- When the equipment is shut down for maintenance, not only should the maintenance content and items of the equipment itself be checked, but also the condition of the connection between the equipment and other systems, and whether the working performance is reliable.

- Regularly compare with industry benchmarks to see if there is room for further improvement.