Introduction

There are a variety of ways to process polymers like plastics. Each method has its advantages and disadvantages and is more suitable for specific applications. Let’s take a look at how they are processed through some interesting animations!

Injection Molding

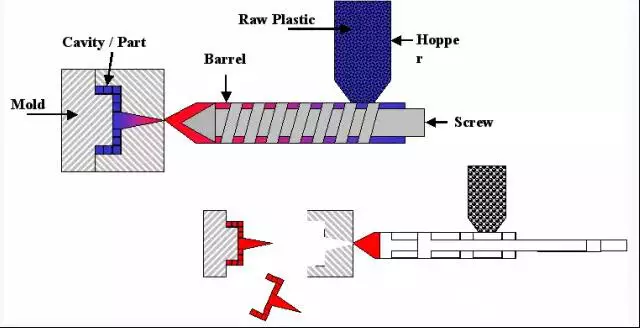

Injection molding is a manufacturing method that creates parts by injecting materials into a mold. The main method of processing plastics is injection molding. In this process, plastic is placed into a hopper, which then heats the plastic and pushes it through a long chamber with a reciprocating screw. After that, it is softened into a fluid state.

A nozzle is located at the end of the chamber, through which the fluid plastic is forced to cool and close the mold. When the plastic cools and solidifies, the semi-finished product is ejected from the press.

1. Plastic Extrusion

Plastic extrusion is a high-volume manufacturing process in which raw plastic material is melted and formed into a continuous profile. The extrusion process is commonly used to make products such as films, continuous sheets, tubes, profiles, rods, jacketed wire, filaments, wire, and cables. With an injection molding machine, dry plastic is placed into a hopper and fed into a long heated chamber. At the end of the chamber, the material is pressed out of a small opening or mold in the shape of the desired final product. After the plastic leaves the mold, it is placed on a conveyor to cool. Blowers are sometimes used during this process to help cool it.

2. Blow Molding

Blow molding is a molding method for manufacturing hollow plastic products. It is a secondary molding technology that uses gas pressure to inflate the rubber-like parison closed in the mold cavity into a hollow product.

3. Thermoforming

A special plastic processing method for processing thermoplastic plastic sheets into various products. The sheet is clamped on a frame and heated to a softened state. Under the action of external force, it is pressed against the mold surface to obtain a shape similar to the mold surface. After cooling and shaping, it is trimmed to form a product. This process is also used in rubber processing. In recent years, new progress has been made in thermoforming, such as continuous production technology from extruded sheets to thermoforming.

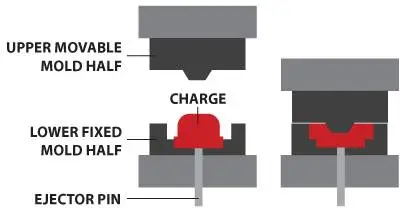

4. Compression Molding

Compression molding is the most common method used with thermoset materials and is not usually used with thermoplastics. During this process, the material is extruded into the desired shape. Plastic molding powder and other materials are added to the mix to produce special qualities. When the mold is closed and heated, the material is hardened into its desired shape. The temperature, pressure and length of time used in the process depend on the desired result.

5. Calendering

Also known as calendering. The last step in heavy leather finishing. It is a finishing process that uses the plasticity of fibers under mixed heat conditions to flatten or roll out parallel fine diagonal lines on the surface of the fabric to enhance the gloss of the fabric. After the material is fed in, it is heated and melted, then formed into a sheet or film, then cooled and rolled up. The most commonly used calendering material is polyvinyl chloride.

6. Extrusion molding

Extrusion molding, the blank is squeezed out from the orifice or gap of the die under the action of three-way uneven compressive stress to reduce its cross-sectional area and increase its length to become the desired product. This processing method is called extrusion, and this processing of the blank is called extrusion molding.

7. Vacuum Forming

Vacuum forming, often called blister forming, is a plastic processing technology. The main principle is to heat and soften the flat plastic hard sheet, then use vacuum to absorb it to the mold surface, and then cool it to form. It is widely used in plastic packaging, lighting, advertising, decoration and other industries.

8. Rotational Molding

Rotomolding is also known as rotational molding, rotational molding, rotational molding, rotational casting, rotational molding, etc. The rotational molding process is to first add the plastic raw material into the mold, and then the mold is continuously rotated along two vertical axes and heated, so that the plastic raw material in the mold is gradually and evenly coated, melted and adhered to the entire surface of the mold cavity under the action of gravity and heat energy, and formed into the required shape, and then cooled and molded, and finally the product is obtained.