Introduction

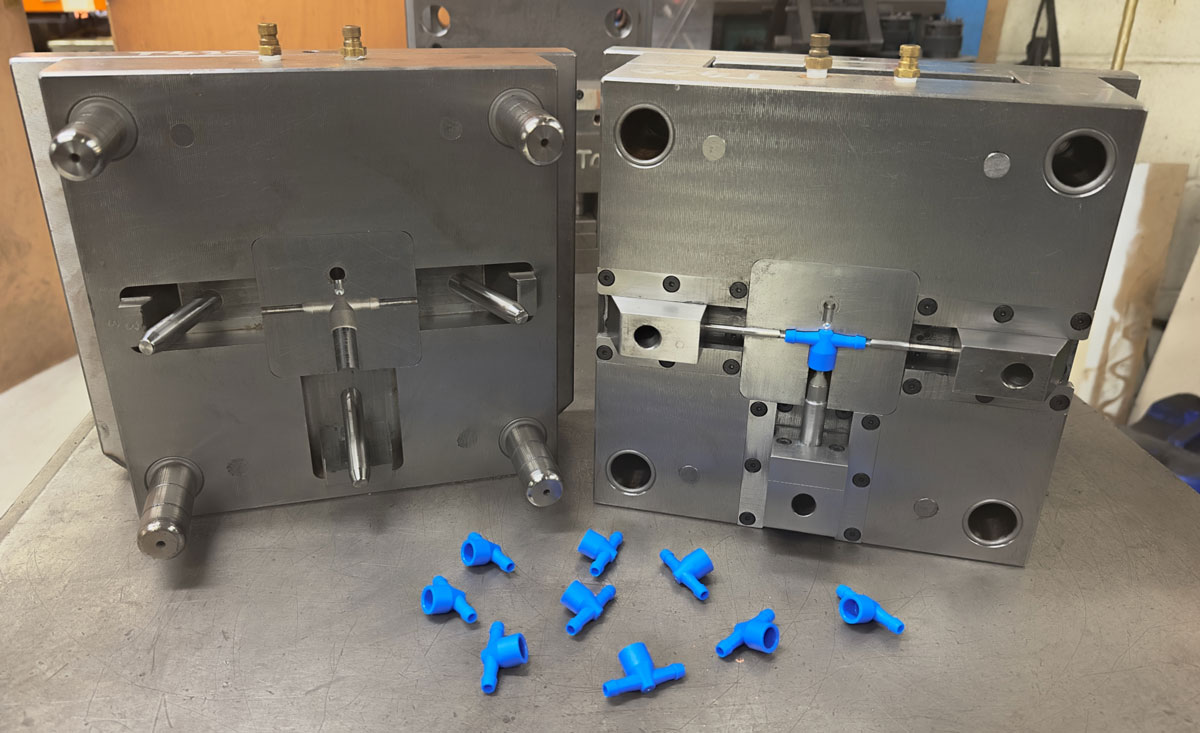

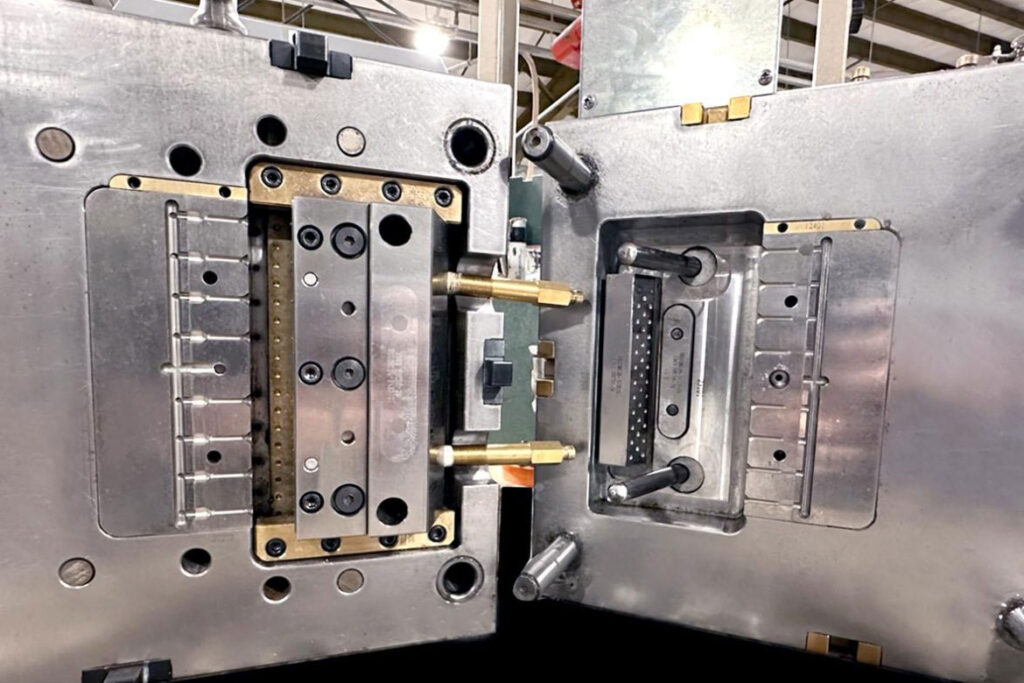

The service life of the mold (i.e. the number of times the mold can stably produce qualified products) is a core indicator that customers are very concerned about. Among the factors that affect the life of injection molds, the choice of mold material is one of the important factors.

For example, a mold made of P20 steel can only produce 300,000 molds at most, but if the mold material is changed to S136 steel, the mold life can reach more than one million molds.

However, the life of an injection mold is not only determined by the material. In addition to the mold material, it is also closely related to the following 8 key factors.

8 factors affecting injection molds

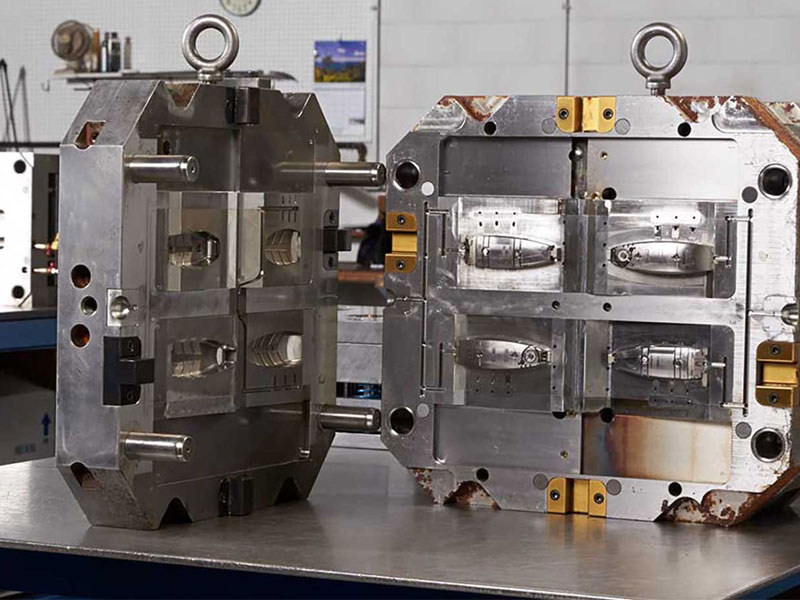

1. Rationality of mold design

Design is the “innate foundation” of mold life. Unreasonable design will cause the mold to bear additional stress during production and accelerate wear and tear.

Structural strength: If the wall thickness of the mold cavity and core is too thin, or the supporting structure (such as ejector pins and guide pillars) is unevenly arranged, deformation and fracture may occur during production due to excessive force. For example, if a large mold is not reinforced with ribs, the cavity may collapse after long-term high-pressure injection molding.

Smooth demoulding: Improper design of demoulding mechanism (such as ejector pin and inclined ejector) will cause product sticking to the mold and excessive demoulding force, which will repeatedly wear the cavity surface or ejector pin. For example, the ejector pin position is offset and the inner wall of the cavity is scratched every time the mold is demolded.

Exhaust system: Poor exhaust will result in the inability to discharge gas during injection molding, forming high pressure impact on the cavity, which will cause long-term wear and burns on the cavity surface, especially for high-temperature materials such as PC and PMMA.

Cooling system: Improper layout of cooling water circuits (such as insufficient local cooling) will lead to uneven temperature in the mold cavity. Under the repeated effects of thermal expansion and contraction, the cavity is prone to cracks or deformation.

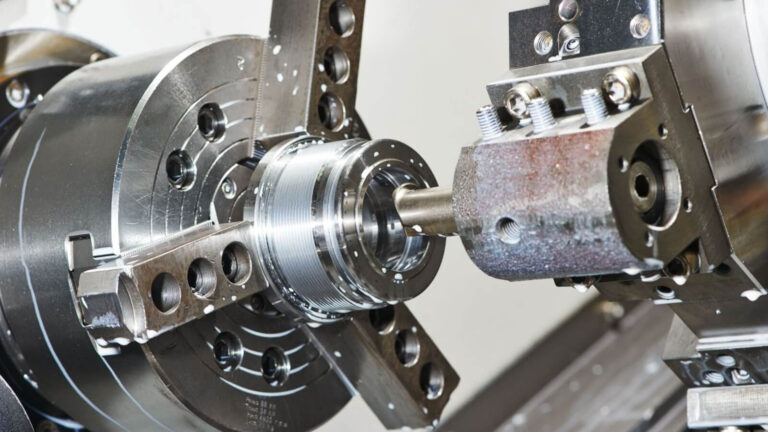

2.Processing accuracy and surface treatment

The processing quality determines the “acquired durability” of the mold. Insufficient precision or surface defects will accelerate the wear of the mold.

Processing accuracy: If the cavity size deviation and the parting surface are not tightly fitted, flash will appear during injection molding, which will in turn aggravate the friction and wear of the parting surface; if the clearance between the guide pin and the guide sleeve is too large, it will cause the mold to shake when opening and closing, accelerating the wear of the guide parts.

Surface roughness: If the cavity surface is not polished enough (such as the Ra value is too high), the friction will increase when the product is demoulded, and the cavity surface will be worn over a long period of time; if there are defects such as knife marks and pores on the surface, these locations will become stress concentration points and are prone to cracks.

Heat treatment process: If the heat treatment after processing (such as quenching and tempering) is not in place, it will lead to uneven hardness of mold parts or internal stress, and local wear or cracking will easily occur during use (for example, the core quenching hardness is insufficient and dents are quickly washed out by the plastic melt).

3.Injection molding process parameter setting

Unreasonable injection molding parameters will cause “extra damage” to the mold, which is equivalent to “using the mold in the wrong way” and will also shorten the life of the mold.

Injection pressure and speed: Too high pressure (exceeding the range of mold design) will aggravate the wear of the cavity and gate; too fast speed may cause the plastic melt to have too much scouring force on the cavity surface, especially for plastics with glass fiber, such as PA66+30% glass fiber, which have extremely strong scouring properties.

Molding temperature: If the mold temperature is too high (such as exceeding the heat resistance limit of steel), it will cause oxidation of the cavity surface and a decrease in hardness; frequent and drastic temperature fluctuations (such as high and low) will cause thermal fatigue and cause cracks in the cavity.

Holding time and cooling time: If the holding time is too long, the continuous stress on the mold cavity will increase; if the cooling time is too short, the mold will be opened before it is fully cooled down, and the accumulation of thermal stress will accelerate aging.

4.Production material characteristics

The physical and chemical properties of different plastics vary greatly in their “corrosiveness” to molds.

Hardness and wear resistance: Plastics filled with glass fiber or minerals (such as PP + 40% glass fiber) are equivalent to “abrasive materials” during injection molding, which will quickly wear out the cavity surface and gate, and their lifespan may be shortened by more than 50% compared to ordinary plastics.

Corrosiveness: Plastics containing chlorine and fluorine (such as PVC and POM) will decompose corrosive gases at high temperatures, which will corrode the mold steel over a long period of time, especially for molds that have not been treated with anti-corrosion.

Viscosity and fluidity: High-viscosity plastics (such as PC) require higher injection pressure, which will increase the force on the mold; low-fluidity plastics (such as PEEK) may cause local high pressure due to filling difficulties, exacerbating cavity wear.

5.Daily maintenance and care

The “maintenance level” of the mold directly determines its lifespan. Lack of maintenance will cause small problems to worsen and accelerate the “aging” of the mold.

Cleanliness: If the residual plastic in the cavity (especially PVC and other easily degradable materials) is not cleaned in time after production, the residual material will corrode the cavity after high-temperature carbonization; if the guide pins and guide sleeves are not lubricated regularly, dry friction will accelerate wear.

Regular maintenance: If wearing parts such as ejectors and springs are not checked and replaced regularly, they may break and get stuck, causing large-scale damage to the mold; if the cooling water circuit is not cleared regularly, scale blockage will lead to poor cooling and cause thermal fatigue.

Storage environment: If the mold is not coated with anti-rust oil and moisture-proof when it is idle for a long time, the cavity will rust; if it is stacked and stored without support, it may deform due to gravity.

6.Quality of mold accessories

The mold is a “systematic project” and any quality defect of a small component may drag down the overall life.

Quality of standard parts: If inferior products are used for ejectors, guide pins, springs, etc. (such as using ordinary carbon steel instead of SKD61 ejectors), they will break prematurely due to insufficient strength and even damage the cavity.

Durability of wearing parts: Parts that frequently contact high-temperature melt, such as sprue bushings and pull rods, will be worn or deformed quickly if the materials or heat treatment are unqualified, resulting in poor feeding.

Hydraulic/pneumatic components: For molds with side core pulling and hydraulic demolding, poor sealing of the oil cylinder and air cylinder will cause movement jams, which will cause uneven force on the mold structure and accelerate damage.

7.Product structure complexity

The more complex the product structure, the more “unconventional stresses” the mold will bear, and the more difficult it is to guarantee its lifespan.

Deep cavity/thin-wall structure: The core of deep cavity products is slender, which is prone to bending and deformation due to melt pressure during injection molding; thin-wall products require high-pressure filling, the cavity is subjected to greater force, and wears faster.

Multiple parting surfaces/side core pulling: For molds with multiple parting surfaces or side core pulling, there are more mating surfaces when opening and closing the mold. If the precision is not well controlled, the mutual friction (such as wear of the slider and the guide groove) will be aggravated.

Insert/Inlay Structure: When the product has a metal insert, the contact area between the insert and the mold will be subjected to additional impact during injection molding; if the joint gap of the inlay-type cavity is too large, flash will appear, thereby wearing the joint surface.

8.Production batch and frequency

The “intensity of use” of the mold will also affect its lifespan. High-frequency and large-scale production will cause more significant damage to the mold.

Production continuity: 24-hour uninterrupted production (such as automotive parts molds) will wear out faster than intermittent production molds because there is no “recovery time” from thermal fatigue and mechanical stress.

Batch size: The cumulative wear of the same mold after 1 million productions is much greater than the situation of maintenance and reproduction after 100,000 productions. Long-term high-load operation will accelerate the aging of parts.

Summary

The life of the mold is the result of the combined effects of design, materials, processing, technology, maintenance and other aspects.

For example, a mold made of P20 steel (medium material) but with proper design, precision processing, and good maintenance may have a longer life than a mold made of S136 steel (high-quality material) but with poor design and poor maintenance.

For customers, choosing a supplier that can take into account “full process control” can better ensure the life of the mold than simply pursuing “high-grade materials”.