During the critical stage of product development, prototype production is a key step in verifying design feasibility. As a professional manufacturer with 15 years of experience in precision prototype production, Gaofeng Prototype Factory , drawing on industry experience, offers an in-depth analysis of the eight key issues to consider when developing prototypes, helping you mitigate development risks and improve verification efficiency.

1.Design document specifications: the first step to success or failure

Accurate design documents are the cornerstone of prototype quality, and we need to focus on:

Format requirements

Prioritize providing STP/STEP format (best compatibility) and avoid using the original format of the design software

Integrity Check

Ensure that the 3D model has no broken surfaces, missing parts or interferences. Complex assemblies require exploded views.

Tolerance Marking

Key matching dimensions must have clear tolerance requirements (Mingmei CNC conventional accuracy ±0.05mm)

Experience warning: Design drawing errors can lead to processing failure or dimensional deviation, causing project delays.

2.Scientific decision-making on material selection

Matching materials to validation targets is key to reducing costs:

| Verification Objective | Recommended Materials | Gaofeng Solution |

|---|---|---|

| Appearance Validation | ABS, PMMA, Photosensitive Resin | 200+ color spray library, supports matte/metallic/transparent effects |

| Structural Testing | PC, POM, 6061 Aluminum Alloy | High-rigidity material processing, assembly accuracy ±0.05mm |

| Functional Prototype | Nylon, PEEK, Stainless Steel | Professional processing solutions for heat-resistant/wear-resistant materials |

Pitfall Avoidance Guide: Avoid gluing POM, nylon, and aluminum alloys; mechanical fixing structures are required.

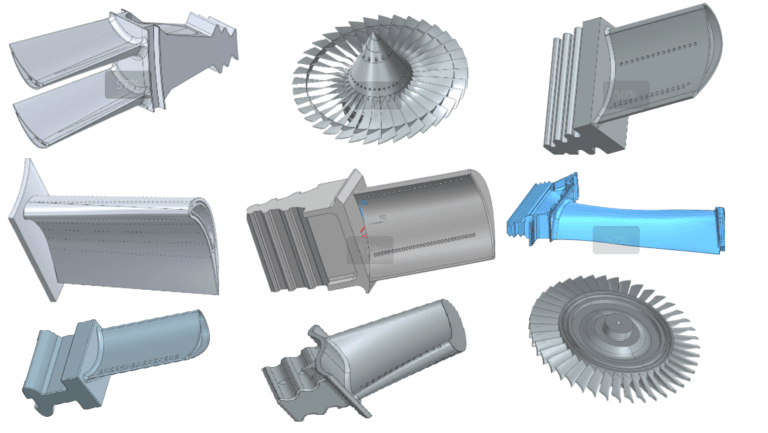

3.Precise matching of processing technology

CNC processing (Mingmei’s core technology)

Advantages

±0.05mm high precision, genuine materials, excellent surface quality

Applicable

Structural verification, assembly testing, small batch production

3D printing (rapid verification solution)

SLA photosensitive resin

0.05mm layer thickness, suitable for fine appearance parts

SLS nylon

Unsupported complex inner cavity structure

Note: 3D printed parts require post-processing to improve surface quality

4.Control the key details of post-processing

Bonding process:

The amount of glue needs to be precisely controlled. Too little will cause cracking, and too much will increase the grinding cost.

Surface treatment:

Oil spraying requires control of dust spots (dust-free workshop), and electroplating requires prevention of blistering (pre-treatment cleanliness)

Special Requests:

Avoid obvious glue marks and bubbles when bonding acrylic

5.Practical skills for assembly verification

- Reserve 0.1-0.2mm assembly clearance (slightly larger than the design value)

- Complex structures are assembled after processing in parts

- Provide assembly guidance video/graphic instructions

6.Confidentiality and Intellectual Property Protection

During the prototyping phase of new products, competitors are more likely to obtain information. Therefore, the following measures should be taken:

Sign a confidentiality agreement (NDA) to limit access to drawings

Choose a manufacturer that completes all processes independently (Mingmei completes the internal processing)

7.Three major strategies for cost control

- Simplify the structure of non-critical parts (such as hidden surfaces)

- ABS+ oil injection is used to replace metal materials for exterior parts

- Small batches of less than 50 pieces use silicone mold technology (cost reduction of 40%)

8.The Gold Standard for Supplier Selection

- Process transparency: Provide photo/video feedback of the processing process

- Response speed: 24-hour technical Q&A (Mingmei standard service)

- Equipment Capabilities: CNC machining center + 3D printing equipment collaborative guarantee