Introduction

Color shading is a common defect in injection molding. It’s not uncommon for entire batches of injection molding machines to be scrapped due to color differences in parts. Numerous factors contribute to color shading, including the raw resin, masterbatch, the mixing of masterbatch and raw material, the molding process, the injection molding machine, and the mold. Because of this wide range of factors, color shading control is generally considered one of the most difficult techniques to master in injection molding. In actual production, we generally focus on the following six aspects to control color shading.

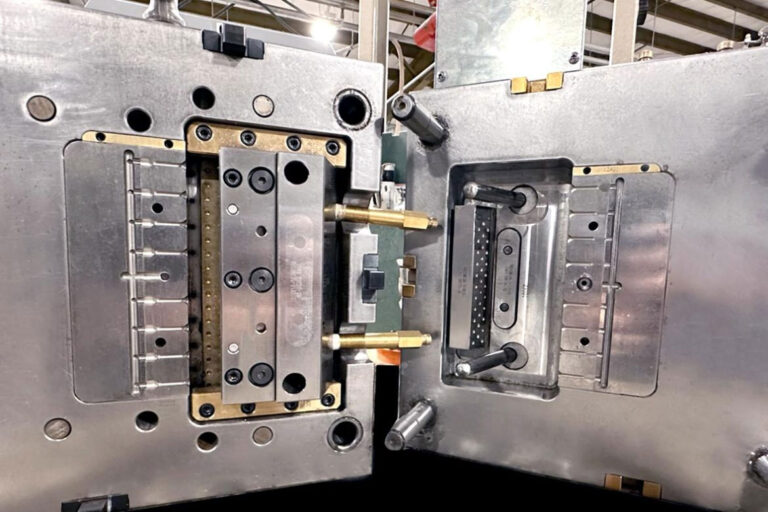

1. Eliminate the influence of the injection molding machine and mold

Choose an injection molding machine with a capacity comparable to the main product being molded. If the machine has problems such as dead zones, it’s best to replace the machine. Color shading caused by issues such as the mold’s gating system and venting slots can be corrected by repairing the corresponding mold sections. Resolving issues with the injection molding machine and mold before commencing production reduces complexity.

2. Eliminate the influence of raw resin and masterbatch

Controlling raw materials is key to completely resolving color shading. Therefore, especially when producing light-colored products, the significant impact of varying raw resin thermal stability on product color fluctuations cannot be ignored.

Since most injection molding manufacturers don’t manufacture plastic masterbatches or color masterbatches themselves, they can focus on production management and raw material inspection. This means strengthening incoming raw material inspection. During production, the same manufacturer and brand of masterbatch and color masterbatch should be used whenever possible.

For color masterbatches, we conduct spot checks and color tests before batch production, comparing them both to the previous batch and the current batch. If the color difference is minimal, the batch is considered acceptable. If there is a slight color difference within a batch, the masterbatch can be remixed before use to minimize color variation caused by uneven mixing. Furthermore, we must focus on inspecting the thermal stability of the raw resin and color masterbatch. If thermal stability is poor, we recommend replacing the manufacturer.

3. Eliminate the effects of uneven mixing of the color masterbatch and masterbatch

Improper mixing of the plastic masterbatch and color masterbatch can also result in erratic product color. After the masterbatch and color masterbatch are mechanically mixed and fed into the hopper via suction, static electricity can cause the color masterbatch to separate from the masterbatch and easily adhere to the hopper walls.

This can cause variations in the color masterbatch amount during the injection molding cycle, resulting in color variation. In this case, the solution is to suck the raw materials into the hopper and then stir them manually. Now many companies use feeders to add masterbatch, which saves a lot of manpower.

It has a significant impact on color difference control and provides significant assistance. However, many companies often encounter unsatisfactory results due to improper use. The amount of masterbatch added by the feeder at a fixed speed depends on the plasticizing time, which itself fluctuates, sometimes quite significantly.

Therefore, to ensure a constant feeding amount, the feeder feeding time must be fixed and set to less than the minimum plasticizing time. When using the feeder, please note that due to the small outlet of the feeder, after a period of use, raw material powder particles accumulated in the feeder screw may cause inaccurate feeding or even cause the feeder to stall, so regular cleaning is required.

4. Reduce the impact of barrel temperature on color difference

In production, color difference is often caused by damage or failure of a heating coil or uncontrolled prolonged heating of the heating control unit, which causes drastic changes in barrel temperature.

Therefore, during production, the heating system should be regularly inspected and promptly replaced and repaired if damaged or out of control, to reduce the likelihood of this type of color difference.

5. Minimize the impact of injection molding process adjustments

When adjusting injection molding process parameters for reasons other than color difference, minimize changes to the injection temperature, back pressure, injection cycle, and masterbatch dosage. While making adjustments, observe the impact of these changes on color.

If color difference is detected, make adjustments immediately. Avoid using injection molding processes that induce strong shear, such as high injection speeds and high back pressures, to prevent color difference caused by factors such as local overheating or thermal decomposition. Strictly control the temperature of each barrel heating section, especially the nozzle and the heating section immediately adjacent to the nozzle.

6.Understand the impact of barrel temperature and masterbatch dosage on product color variation

Before making color difference adjustments, it is important to understand how product color changes with temperature and masterbatch dosage. Different masterbatch colors exhibit different color variations with changes in production temperature or masterbatch dosage.

This pattern can be determined through color testing. Unless the color change pattern of the masterbatch is known, it is impossible to adjust the color difference quickly, especially when using a new masterbatch for color adjustment.