Introduction

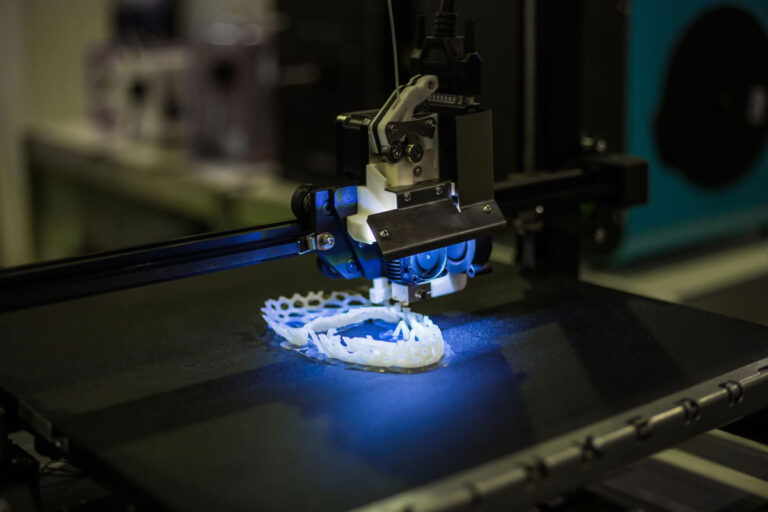

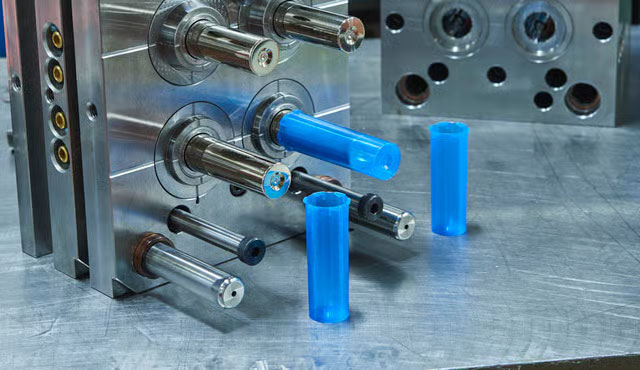

In the production of plastic products, 3D printing and injection molding are relatively common processes.

One of the advantages of 3D printing over injection molding is that it can quickly produce products without the need for molds, saving mold opening fees and time. Injection molding, on the other hand, requires injection molds, and the cost of opening injection molds is not low.

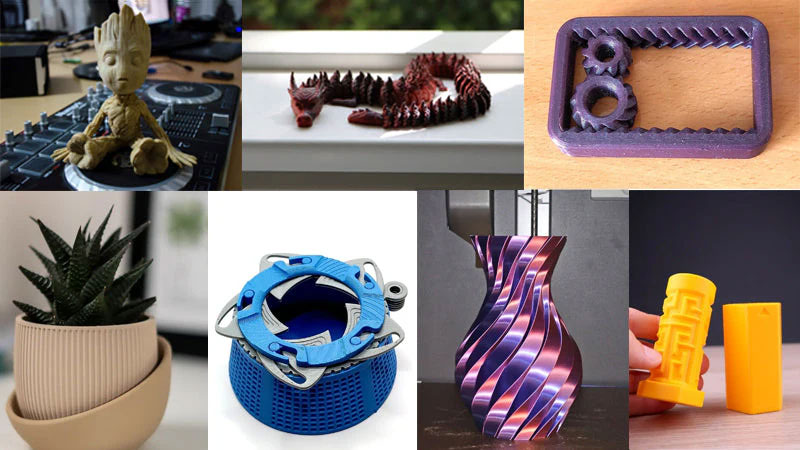

In addition, 3D printing has some other advantages, such as the ability to manufacture complex products that injection molding cannot, such as hollow structure products, internal layered pipes, etc.

However, although 3D printing is so good, it is difficult to replace injection molding. Why is this?

Why is it difficult for 3D printing to replace injection molding?

3D printing can’t replace injection molding simply because it has several major flaws. If these flaws aren’t addressed, injection molding won’t be replaced even in another 100 years.

First of all, the production efficiency is low.

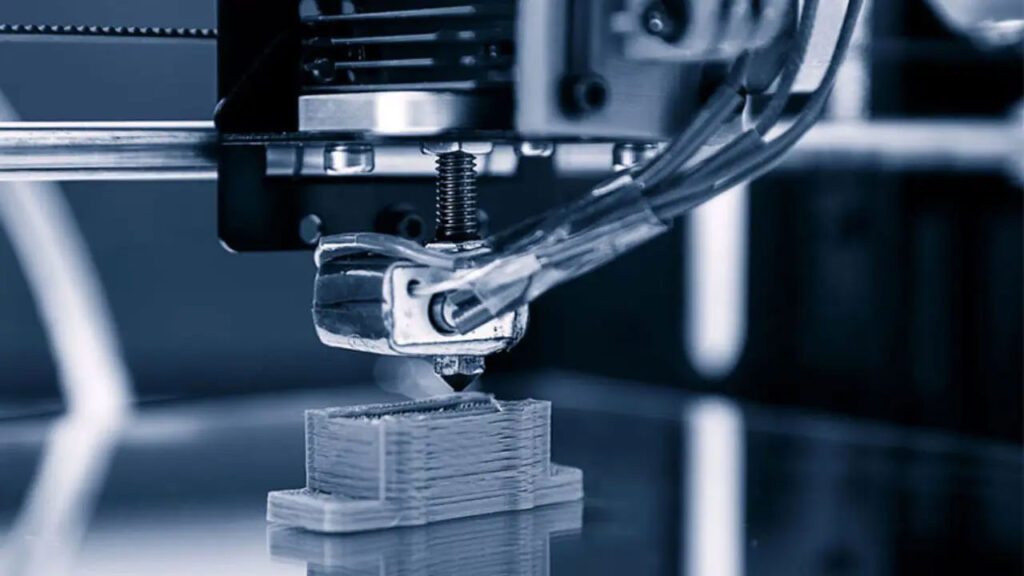

3D printing, which builds products by depositing materials layer by layer, is relatively slow, and complex products may take hours or even days to complete. Injection mold production, on the other hand, can produce multiple products in seconds (multi-cavity molds).

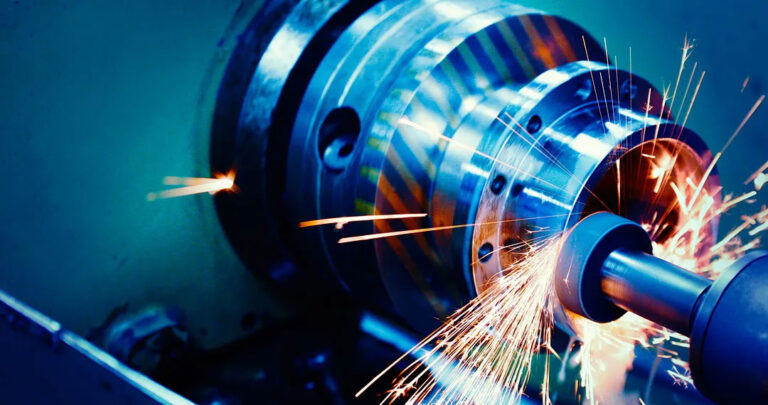

Therefore, if the product needs to be mass-produced, the high-efficiency injection molding process has obvious advantages over 3D printing.

Secondly, the achievable accuracy is limited.

The overall precision achieved by 3D printing is lower than that of injection molds. Although top-tier 3D printing can achieve the same level of precision as injection molding, top-tier injection molds can achieve even higher precision. Furthermore, top-tier 3D printing has relatively high requirements for equipment and materials, resulting in significant limitations.

In addition, 3D printing is not as stable as injection molds in the production of high-precision products. Even if injection molds are used for large-scale production, they can ensure the consistency of products very well. However, 3D printing cannot do this. Products produced in different batches are prone to dimensional deviations.

Again, there are limitations in product performance.

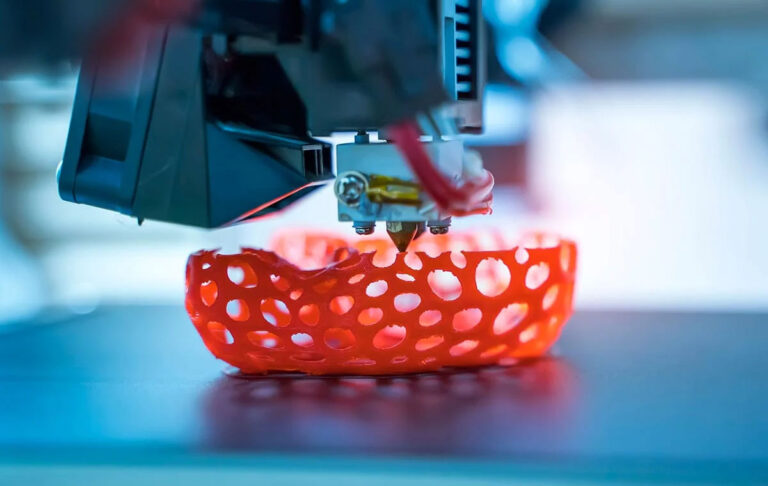

Plastic products manufactured using 3D printing have limitations in terms of strength, temperature resistance, and other performance. Even if made of the same material, 3D-printed products are not as strong as injection-molded products.

For example, a plastic stool made with 3D printing can be made very personalized, like a work of art, but if you really want people to sit on it, it may break into pieces as soon as they sit down.

Finally, the post-processing process is complicated.

Products manufactured using 3D printing require post-processing, including support structure removal, surface polishing, and curing (e.g., photosensitive resin requires UV exposure). Some processes also require specialized equipment, increasing time and cost. Products manufactured using injection molding, on the other hand, require simple post-processing, and some products can even be used without any post-processing.

Cost comparison between the two

1.Equipment cost

The unit price of industrial-grade 3D printers (such as FDM and SLA) is usually tens of thousands to hundreds of thousands of Dollars, and the cost increases sharply when multiple devices are required to meet large production volumes.

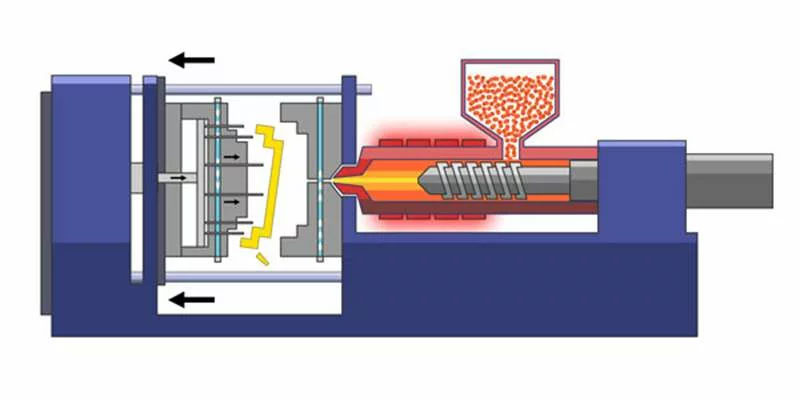

The unit price of injection molding machines varies according to tonnage. For example, a 100-ton injection molding machine costs about 2000$ to 300,00$, and the production capacity of a single machine is high.

2.Mold cost

3D printing does not require molds, saving mold-making costs. Injection molding requires custom molds, and the cost increases with the complexity of the product.

3.Material cost

3D printing plastic consumables (such as PLA and ABS) cost approximately 10$-30$ per kilogram, with some specialty engineering plastics (such as PEEK) costing even more. Material utilization rates exceed 90%, minimizing waste. Plastic pellets for injection molding cost approximately 1.5$-5$ per kilogram, offering low raw material costs. However, waste from the injection molding process, such as gates and runners, must be recycled (utilization rates are approximately 70-80%).

4.Production efficiency

Single-piece printing takes a long time. For example, conventional FDM printing of a 20cm part can take several hours, requiring multiple machines to produce in parallel, increasing labor and monitoring costs. Injection molding cycles are short. For example, the injection molding cycle for simple parts is about 10-30 seconds. A single machine has a high daily output, making it suitable for large-scale production.

5.Post-processing costs

3D printing requires support structure removal, surface polishing, and curing, and post-processing costs for complex parts can account for 30%-50% of the total cost. Injection molding offers simple post-processing (limited to deburring and quality inspection), high automation, and low costs.

From a cost perspective, 3D printing is more advantageous for small-batch production (e.g., fewer than 1,000 units). This is because injection molding requires molds, and when production volumes are low, the mold costs are spread across the product, resulting in higher production costs.

For example, a cultural and creative enterprise produces customized plastic ornaments. The total cost of 3D printing 100 pieces is about 5,000 yuan, and the cost per piece is 50 yuan. If injection molding is used, the mold opening fee is 20,000 yuan, and the cost per piece rises to 200 yuan.

When product output exceeds a certain value, the cost of injection molding production will begin to be lower than 3D printing.

As production increases, the average mold opening fee will become lower and lower, and its proportion in the product production cost will also become smaller and smaller. After deducting the mold opening fee, the cost of injection molding production is much lower than that of 3D printing. Therefore, as the impact of mold opening fees on costs becomes smaller and smaller, injection molding production will become more and more cost-effective.

Taking the above example as an example, when the output increases to 10,000 pieces, the amortized cost of mold opening fee is only 0.3$. If the cost of producing a product using injection molding process is 0.8$, the total cost of the unit product is only 1$.

With 3D printing, however, the impact of increased production on the cost of a single product is much smaller. The cost difference between producing 100 units and 10,000 units isn’t that significant. Even if the cost of a single unit drops from 8$ to 5$, injection molding still offers a significant cost advantage.

Conclusion

Therefore, for plastic products with a production volume of more than 10,000 pieces, it is often more cost-effective to produce them with injection molds.

For products between 1,000 and 10,000 pieces, it depends on the critical value between the two. Below the critical value, 3D printing may be more cost-effective, while open mold injection molding is more cost-effective.

In short, open mold injection molding cannot be replaced by 3D printing due to its advantages in production efficiency, process precision and low cost of large-scale production.