Introduction

3D printing technology, with its high efficiency, precision, and flexibility, has attracted widespread attention and application in the industrial market. Among 3D printing technologies, light-curing printers are particularly popular.

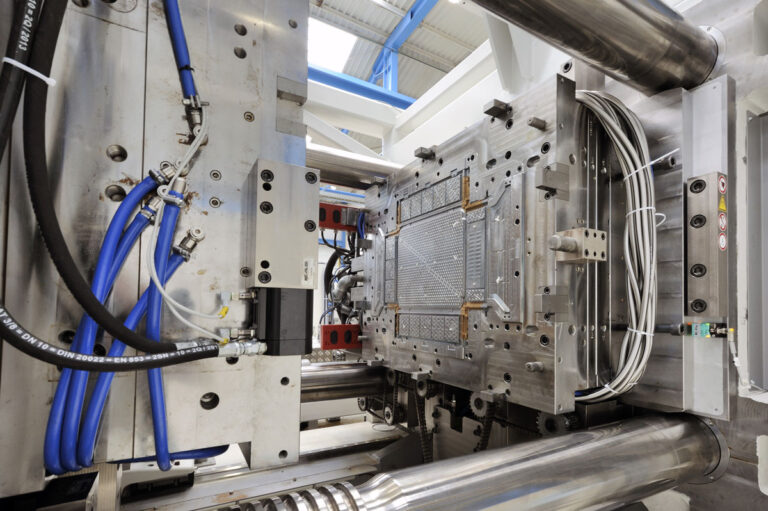

A stereolithography printer is a 3D printer that uses ultraviolet light to cure resin. Through ultraviolet light, the liquid resin solidifies into a solid form in a short period of time. Compared to traditional melt-thickening printers, stereolithography printers offer significant advantages in printing speed, accuracy, and surface smoothness.

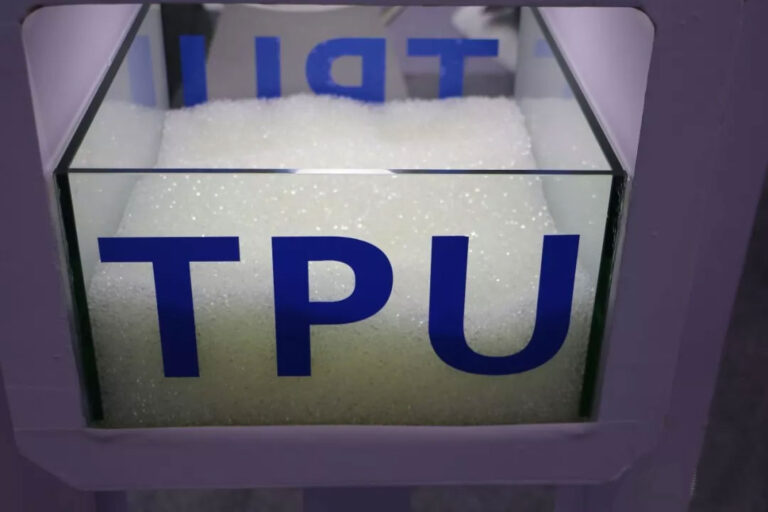

The photosensitive resin most commonly used in light-curing printers is a polymeric resin material, a type of light-curing material. This material is liquid at room temperature and can undergo a polymerization process under strong ultraviolet irradiation, thereby causing a curing reaction.

It is converted from liquid to solid. Therefore, this material is often used as printing consumables in the light-curing rapid prototyping technology in 3D printing. The market price of this material is relatively moderate. It is more expensive than thermoplastic resin materials, but lower than metal powder materials. The price is mainly concentrated between 78 and 150 yuan per kilogram. Now let’s take a look at the advantages and disadvantages of photosensitive resin materials.

Advantages of photosensitive resin

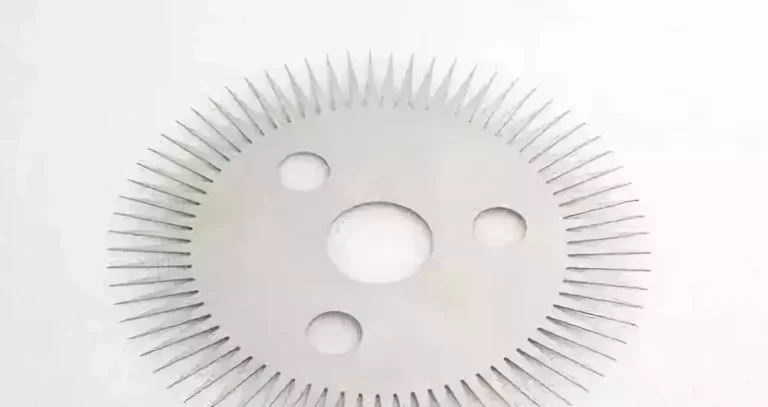

Models made of photosensitive resin materials are of high quality and have good toughness, and the printed models can remain unchanged for a long time.

At the same time, the surface of the model printed with photosensitive resin is very precise, smooth, and rich in details. During the printing process, the material can maintain good fluidity, has a good overall shaping effect, and is easy to form!

Disadvantages of photosensitive resin

Photosensitive resin materials have very high requirements for storage. They cannot be placed in ventilated areas or directly in the sun. They need to be stored in a dry place away from light.

Moreover, liquid materials need to be contained in special containers and stored in sealed, classified and isolated areas.

In addition, the material emits irritating gases during the printing process and is slightly toxic.

Long-term contact can affect human health, especially for patients with rhinitis, as it can further aggravate rhinitis. Direct skin contact can also cause dermatitis and allergies. So be careful!

Conclusion

In general, photosensitive resin materials as 3D printing consumables have excellent printing effects and good fluidity, making them the best choice for making precision models.

However, during use, attention should also be paid to the storage and protection of materials to ensure human health.

I believe that with the continuous advancement of technology, photosensitive resin materials are also constantly improving, and in the future it will play a greater role in medical devices, art design and other fields.

At the same time, as market competition intensifies, the price of photosensitive resin materials will gradually decrease, allowing more companies and individuals to use the material for production and innovation, creating more commercial value.