Photosensitive resin is composed of polymer monomers and prepolymers, to which light ( ultraviolet light ) initiator ( or photosensitizer ) is added . When irradiated with ultraviolet light of a certain wavelength (250-300 nanometers ) , polymerization reaction will occur immediately and curing will be completed. Photosensitive resin is generally in liquid state and is generally used to make high-strength, high-temperature resistant, waterproof and other materials.

Applications:

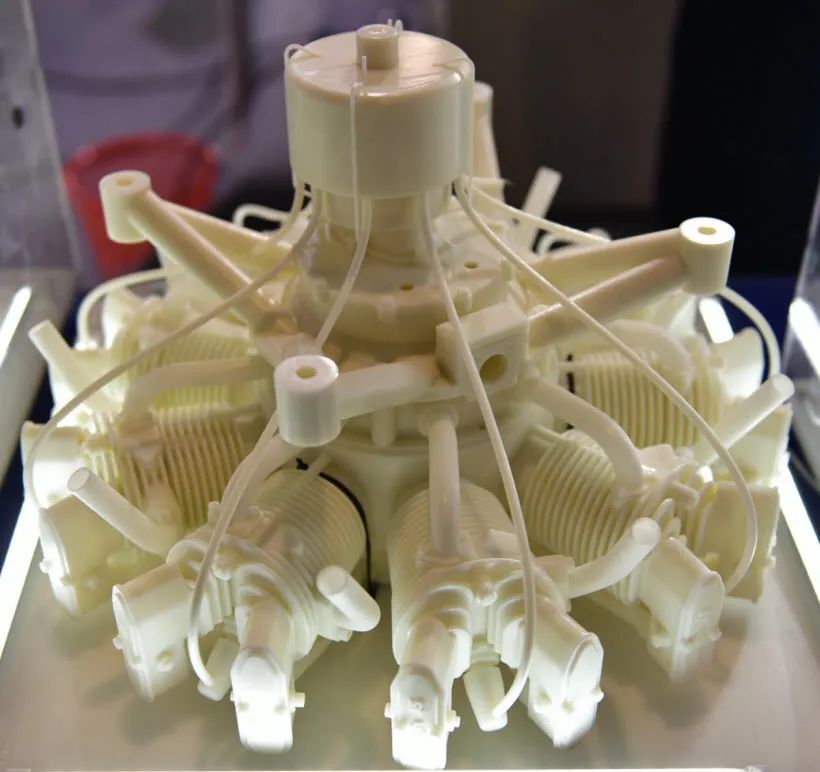

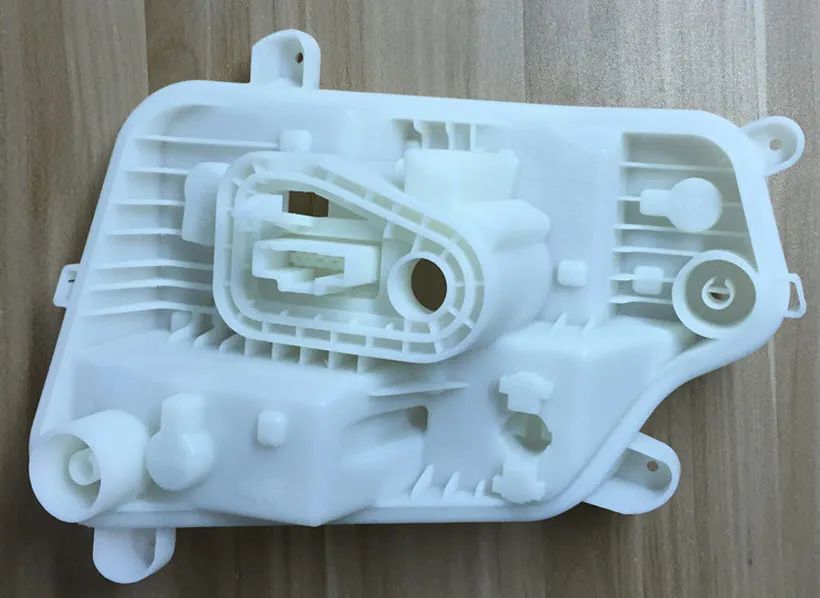

This material is similar to traditional engineering plastics (including ABS , PC , PBT , etc.). It can be ideally used in the production of samples for automobiles, medical devices , and daily electronic products. It is also used in water flow analysis, room temperature vulcanized silicone rubber models, storable conceptual models, air duct testing, and rapid casting models. It is also used in the production of small models, prototypes, and jewelry casting and laminating.

Performance characteristics:

It can produce durable, hard and waterproof functional parts. It has the characteristics of fast curing, high molding precision, good surface effect, ABS -like performance, high mechanical strength, low odor, storage resistance, strong versatility, assembly, self-tapping screws, surface painting, surface silk screen printing, etc. It is suitable for domestic mainstream SLA rapid prototyping equipment.

Common technical parameters:

Molding method: SLA

Forming accuracy: ± 0.1% × L ( L>100mm )

Product strength: Standard

Minimum wall thickness: 0.4mm or more

Printing cost: Low

Surface roughness: smooth

Heat deformation temperature: 55 ℃ ( 0.46MPa )

Print support: Yes, manually removed

Surface post-treatment: surface polishing, painting, silk screen printing, UV

Product Application:

1. Product shell, used for appearance and structure verification

2. Product internal structure, used for assembly verification

3. Complete product verification

4. Prototypes and samples

5. Small batch production ( 1-200 pieces)

Printing advantages:

1. Fast delivery: 24 hours delivery

2. Low cost: The lowest price in 3D printing

3. Surface: Smooth surface

4. High precision: can meet daily needs