Introduction

Traditional jewelry making is a meticulous and time-consuming process. No one can deny the skill and craftsmanship that goes into a handmade ring or pendant, and there is always something unique about a hand-carved personal ornament. But the fact is that making jewelry completely by hand requires a great deal of time, patience, and skill.

3D printing enables anyone to produce unique, high-quality jewelry, while also providing professional jewelers with a new solution for jewelry production that is cheaper, simpler, and faster. The emergence of 3D printing technology has disrupted the jewelry market and inspired new technology-based jewelry companies to provide customers with convenient customized manufacturing services.

1.Why choose 3D printed jewelry?

Most of the time, when we talk about 3D printed jewelry, we mean 3D printed wax models that are then used to make molds, just like traditional jewelry making. While it is possible to 3D print directly in precious metals, most jewelers use 3D printers to make models from digital designs, replacing hours or days of hand carving and the skills required with almost the click of a button. Depending on the size of your 3D printer, you can print nearly ten castable wax models at once.

There are many other advantages to using a 3D printer to make jewelry. You can use 3D printing to make prototypes to ensure that the finished product is exactly what you and your client want. This is especially useful if you decide to produce multiple versions of the same design.

2.Design your own jewelry

The first step to 3D printed jewelry is digital design. Once you have a concept in mind, you must create it using computer-aided design (CAD) software. There are a variety of 3D design software options to choose from to suit your needs.

If you’re not interested in designing jewelry from scratch, editing an existing design might be more palatable. 3D design libraries like Thingiverse have tons of amazing designs for you to choose from.

Have you searched through all the 3D model libraries and still can’t find the perfect design? If you want to use your favorite antique heirloom or a friend’s work, why not try 3D scanning?

Jewelry Design Software

CAD software is perfect for structural arts like jewelry design. It allows you to maintain precision in the small areas required for jewelry design. In addition, it helps to create uniformity where it is needed, such as earrings, wedding rings, and any mass-produced products.

Most CAD programs with 3D modeling capabilities will be able to support the general idea of jewelry design. The basic principles and even proportions are sometimes the same as designing small machinery. If your design needs to lie flat, like some types of necklace pendants, you may find a non-specific 2D CAD program useful as well.

However, if you are looking for a CAD specifically for designing jewelry , especially a professional-level CAD, there are a few extra considerations that will make your job easier:

Jewelry-specific templates: These templates allow you to worry less about the technical part and focus more on the creative part of your design. Using templates for basic, standardized jewelry components, such as earring backs, makes it easy to conform to industry standards while still showing off the uniqueness of your design.

Realistic Modeling: Since jewelry is a visual medium, a program with 3D modeling capabilities can show you how your design will look in the real world and help you spot any flaws or problems before you make a prototype. This way, you’ll save yourself the heartache when you discover something went wrong during the design process.

Simple interface: A clean workspace with easy-to-find tools and features will minimize your learning curve and maximize your design time.

3. 3D Printed Jewelry

When it comes to 3D printed jewelry, we mentioned that there are two main methods: one is direct 3D printing, which is to print the final work directly from metal or plastic; the other is investment casting, which is to 3D print a wax model and then cast the work based on the wax model.

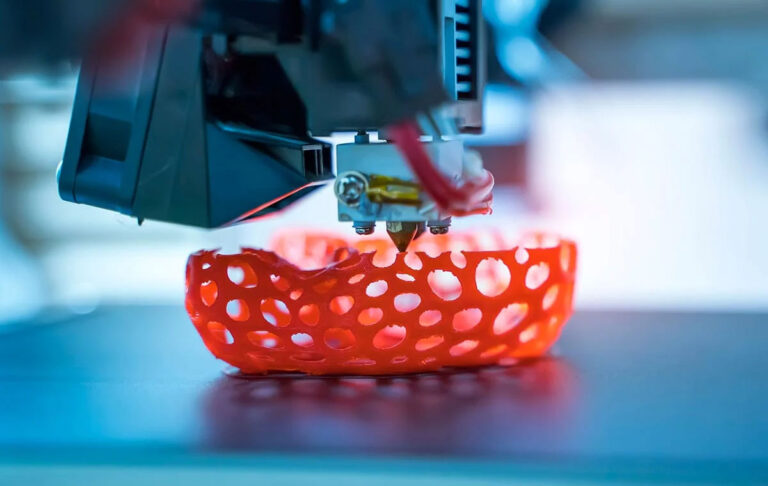

Direct 3D printing

You can 3D print jewelry directly out of precious metals. Most jewelers don’t use 3D printers this way because they are not cheap for independent jewelers.

Direct 3D printing uses a laser to sinter metal powder particles together using a powder bed fusion technique, also known as selective laser melting ( SLM) or metal laser powder bed fusion. You can also use another 3D printing technique called binder jetting, which works with metals or polymers. The type of metal available depends on the 3D printer used.

A 3D printer filled with gold powder is an investment, but luckily, the material that isn’t used up when producing one batch of jewelry can be reused in the next. In addition, you can also print jewelry out of polymers, ceramics, and non-precious metals.

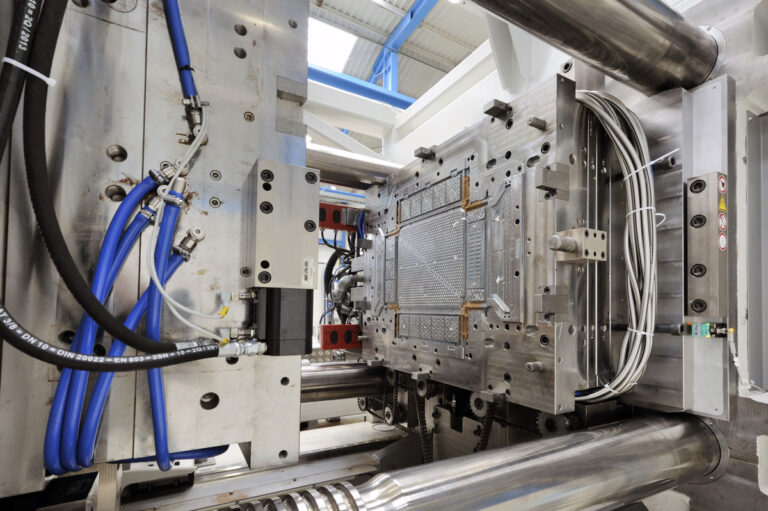

Investment Casting

Investment casting is the most popular method of 3D printing jewelry. It combines 3D printing with traditional mold making techniques. 3D printers replace the practice of carving hard model wax into the desired shape. Jewelers use computers and jewelry design software or any computer-aided design (CAD) software to design, and then 3D print out the jewelry model using wax or other materials such as resin. Resin casting models can be printed through stereolithography (SLA) or digital light processing (DLP). From this point, it’s back to the traditional lost wax casting process.

If you’re not familiar, lost wax casting involves encasing a wax or resin model in a plaster-like medium, which is then heated to harden. This causes the model to melt, leaving a mold that is then filled with molten precious metal. This is the traditional metal casting process. Once the metal solidifies, the mold is removed and the object is carefully removed, machined and polished.

3D printers can not only make a detailed master model, but also customize the digital file of the jewelry through software in a few minutes and print out another model or 20 different models at the same time. This greatly speeds up the design iteration and mass customization. This method is good because you don’t need a special form of metal, most metals can be used.

4. Advantages of 3D printing design models:

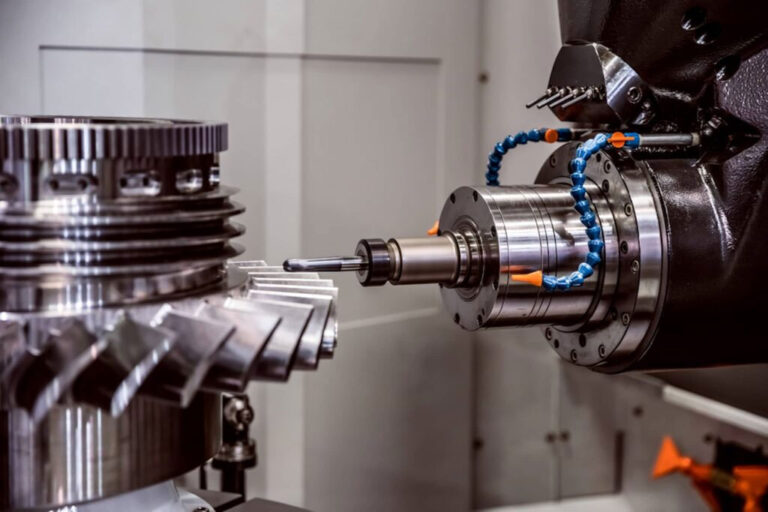

Speed: Simply put, 3D printing is much faster than carving wax by hand. While traditional methods can take hours or even days to meticulously carve a wax model, a 3D printer can produce a detailed model in just hours. It’s also much easier to make changes, since you can simply modify the digital file and print out another version.

Complexity: 3D printers can print much more complex and intricate geometries than hand carving . You can print anything that can be designed with CAD software, so it makes great designs more accessible even to artists who lack carving skills. Plus, depending on the piece, you can even create geometries that would be nearly impossible to carve by hand.

Customization: Since the original master model is stored as a digital CAD file, you can quickly modify the master model according to the customer’s requirements. You can provide customized jewelry and easily modify the model if the future wearer is not satisfied with the initial design.

Batch production: Depending on the capabilities of your 3D printer, you may be able to print dozens of different wax-up models at once.

Reproduction: Another benefit that 3D printing brings you is that you can replicate old jewelry. Using a 3D scanner, you can recreate existing jewelry into a digital model, then clean it up in CAD software and print it out.

Cost-effectiveness: Jewelry-grade 3D printing uses very little printing material. While castable wax materials may be more expensive than regular printing materials, a batch of material can be used in large quantities, helping to reduce material costs.

Rapid Prototyping: Before casting the final piece, the stone is placed into the 3D printed model to ensure a perfect fit and customer approval. The customer can try on the 3D printed model to get a more realistic effect of the final piece than a 2D image.

5. Wax and Casting Materials

Casting materials are not all the same. Sure, you can print with pure wax, but newer materials like castable resins offer properties like greater strength and cleaner burning during the casting process.

For example, polymethyl methacrylate ( PMMA) is an acrylic plastic that has excellent burning properties and is often used in industrial casting. These materials are not always suitable as direct replacements for wax, as some may negatively interact with phosphate-bonded and gypsum-bonded investment materials. Therefore, make sure your casting material matches your investment material.

Your 3D printer may only be compatible with wax made by your device manufacturer . However, if your printer is compatible with third-party materials, there are a few things to keep in mind when purchasing casting materials:

Melt Time: How long does it take for the wax or castable resin material to completely melt or burn out of the mold? Two hours or five hours?

Ash Levels: Low-ash or ash-free wax materials leave little residual ash or smoke in the mold after burnout, while other wax materials may require thorough mold cleaning.

Low Shrinkage: All waxes and castable materials will shrink to a certain extent and you need to take this into account, so it is important to know the shrinkage factor, which should be listed on the material’s technical data sheet.

Low moisture absorption: Most castable resins will absorb moisture if left uncovered, so start by choosing a resin that has some moisture resistance and then store it in a cool, dry place.

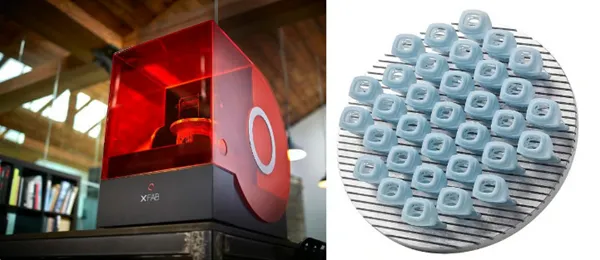

6. Jewelry 3D Printer

The first thing to consider when choosing a jewelry 3D printer is the technology. Most jewelers who want to print casting models choose resin-based 3D printers because of their high printing resolution. Wax resins specifically made for casting allow jewelers to print detailed models that can be fired cleanly.

For direct printing of precious metal jewelry, there are fewer options.

Things to note when choosing a printer:

Resolution: Jewelry is small, so the finer the detail your printer can produce, the better. You should choose a machine that can produce the finest detail, ideally down to 10 microns. For reference, the average width of a human hair is 75 microns.

Printing speed: It’s hard to imagine that hand-carving a wax figure would be faster than 3D printing one, so when it comes to speed, we have to mention 3D printers. Ideally, you can choose a machine that can adjust the speed to get super fast but less detailed prototypes as well as extremely fine details, which usually take longer.

Material compatibility: Choose a printer that isn’t limited to materials from one manufacturer. There may be a wax resin made by a third party that’s best suited to your application. Proprietary materials are usually more expensive than third-party materials, but some printers can print perfectly with their own resins, reducing the chance of trial and error.

Cost: When buying a printer, you have to consider not only the price of the printer, but also the cost of maintenance and materials. Although jewelry 3D printers can pay for themselves within a few months, you still have to pay attention to your budget.

Exposure: If your design has fine features and smooth surfaces, then you need to be careful with LCD technology. Some LCD machines produce models with a pixelated surface, which can affect the casting of the final piece unless you take the time to do some post-processing.

Volume: If you only plan on making one to six models at a time, a low-volume machine will do the job, but if you think you’ll be mass-customizing hundreds of rings or pendants, a high-volume machine will be necessary.

Accessories Your model can’t just come out of the printer. You’ll need some other equipment, like a washer and a curing machine (although you can do without them). So look for a company that can provide a full set of equipment.

No matter how good a printer’s paper performance is, to evaluate whether it’s right for your workstation, you can ask the manufacturer for print samples. Most manufacturers are happy to show you their printers’ actual performance.