Introduction

Each piece of waste material was bought with money, and each circle of the high-speed rotating tool represents the expenditure of money .

Of all the parts processing techniques, CNC machining is probably one of the most expensive .

This article will introduce 16 R&D cost reduction techniques for CNC machining.

Costs of CNC Machining:

1) Processing time

The longer the machining time, the higher the CNC cost. Machining time is the main driver of CNC cost.

2) Material cost

The cost of blank material is an important part of CNC machine cost. Material cost can be reduced by optimizing the design, using standardized blanks as much as possible, and reducing waste.

3) Installation time

When the batch size is small, the preparation of the geometric model and the planning of the machining process have a significant impact on the CNC cost. This part of the cost is a fixed cost that can be spread over large-scale production.

4) Other design factors

When CNC part design has special requirements (such as close tolerance requirements and thin-wall design), special tools, more precise quality control, lower processing speeds, and more complex processing steps are required, which will seriously affect CNC costs.

Once we understand the cost drivers of CNC, we can take appropriate R&D cost-cutting measures to reduce CNC costs.

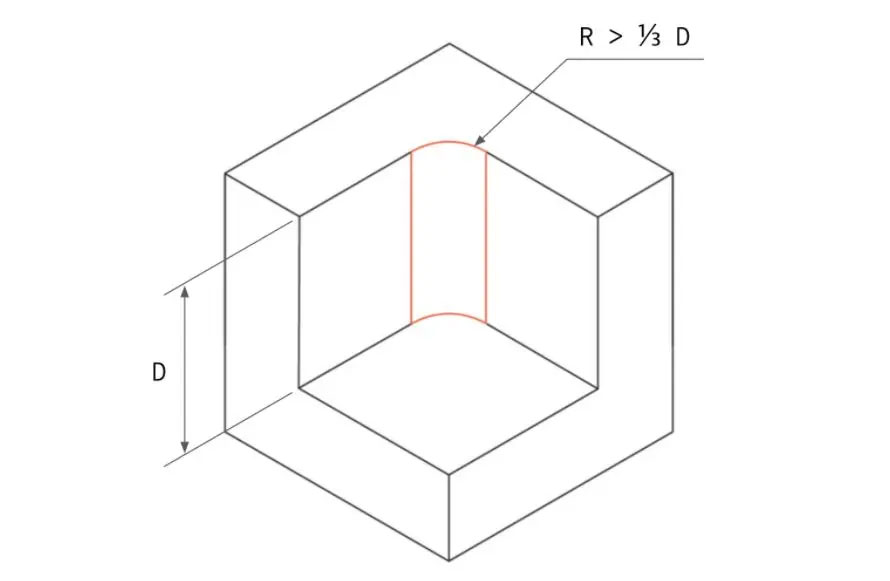

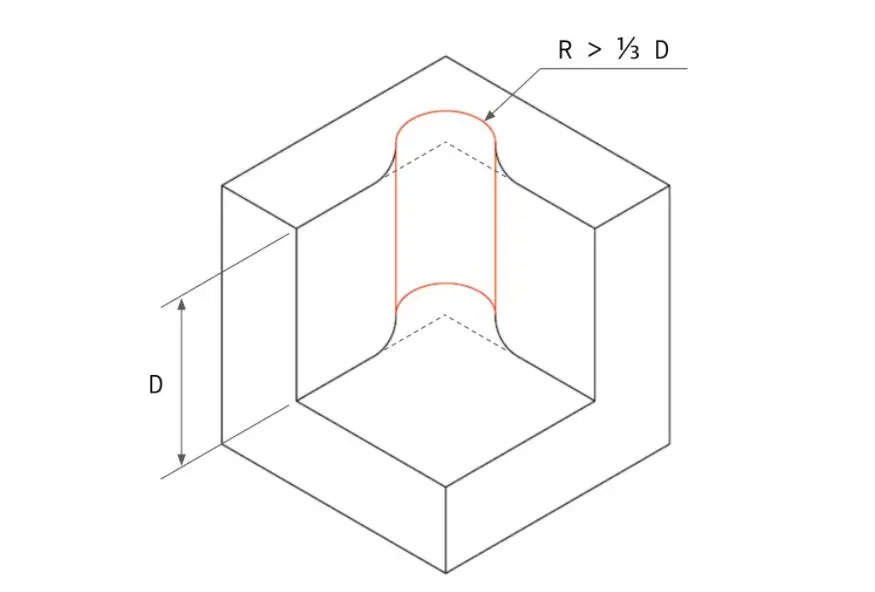

1, R&D Cost Reduction #1 – Rounding of Internal Vertical Angles

All CNC tools have a cylindrical shape. When machining a slot, a fillet with the same size as the outer shape will be generated at the connection between the vertical surfaces of the slot.

If the radius of the vertical connection of the groove body is too small during product design, a small tool will be needed, which means increasing the processing time because the processing efficiency of a small tool is not as good as that of a large tool – this will lead to an increase in processing time and cost.

To reduce costs:

+ The radius should be at least 1/3 of the tank depth, the larger the better;

+ All fillets are the same size; this allows the same tool to be used for the entire process;

+ Design a very small fillet (0.5mm or 1mm) at the root of the slot, or do not fillet it.

+ The ideal For example, if the groove depth is 12mm and the radius is designed to be 5mm or larger, an 8mm diameter tool (4mm radius) can be used during machining to ensure machining efficiency.

+ If filleting is not possible due to design requirements, for example, if another square part needs to be matched here, in order to avoid small fillets, the following design can be used:

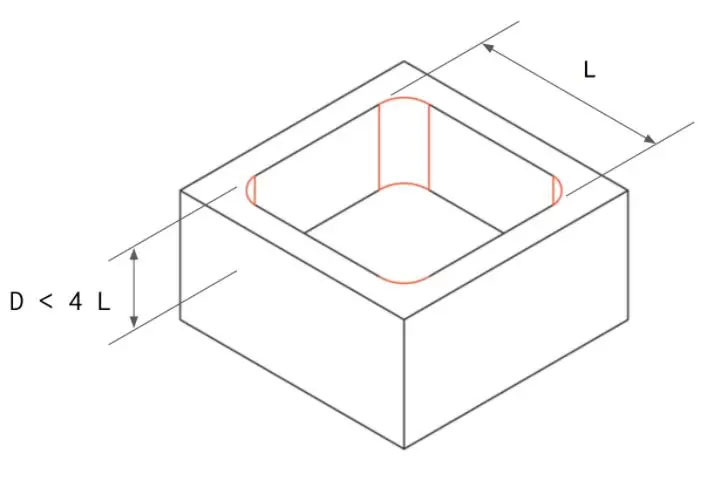

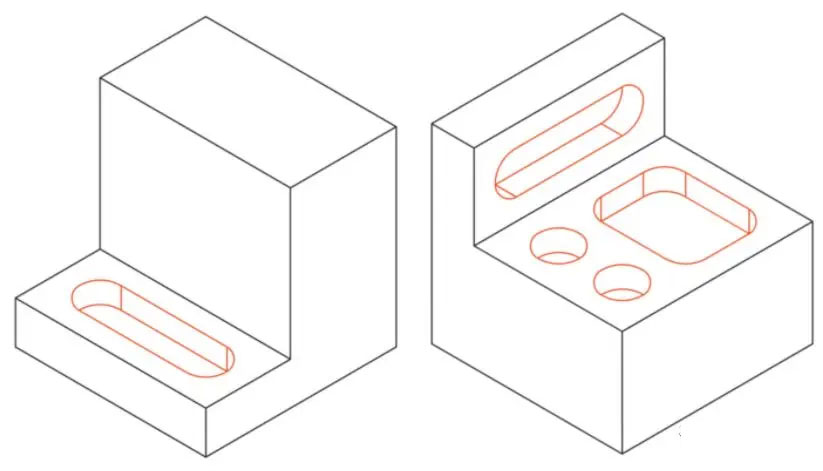

2, R&D Cost Reduction #2 – Reduce Tank Depth

Slot machining significantly impacts part cost because a large amount of material needs to be removed, which significantly increases machining time.

CNC tools have a certain limit on the processing depth. The best processing performance is when the groove depth is 2 to 3 times the tool diameter. For example, a milling cutter with a diameter of 12mm can safely process a groove to a maximum depth of 25mm.

Of course, it is possible to machine deeper slots, up to a maximum of four tool diameters, but this will increase costs, especially when using multi-axis CNC machines.

To reduce costs:

+ The depth of the tank shall not exceed 4 times its length.

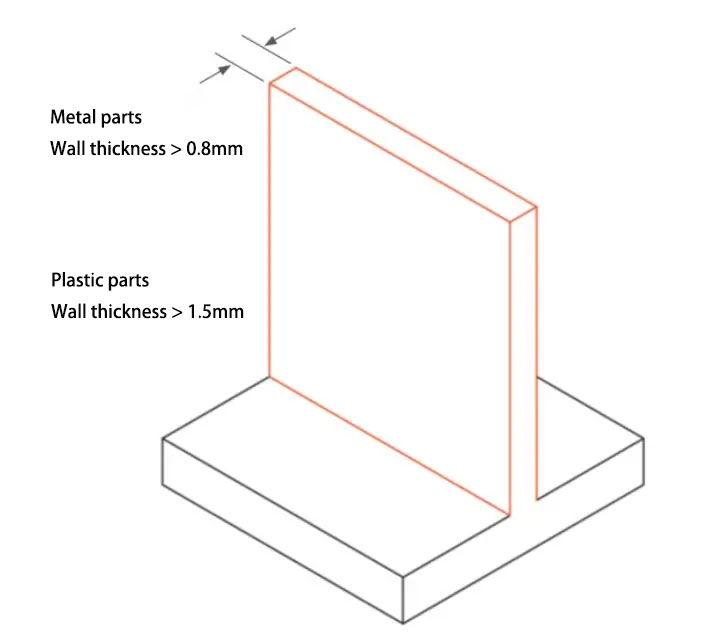

3, R&D Cost Reduction #3 – Avoid Thin Walls

Unless otherwise required, thin-wall designs should be avoided because thin walls are not strong enough and the processing cost is high.

Thin walls are prone to deformation and even cracking during machining. To avoid this, more complex machining paths are required, which consumes more machining time. Thin walls are also more prone to vibration, making high-precision machining of thin walls a significant challenge.

To reduce costs:

+ For metal parts, the wall thickness should be at least 0.8mm, the thicker the better.

+ For plastic parts, the wall thickness should be at least 1.5mm, the thicker the better.

+ The minimum thickness of metal parts can be 0.5mm, and the minimum thickness of plastic parts can be 1mm, but this is not recommended;

When designing holes (including through holes and screw holes) or slots on the edge of a part, thin walls often occur and you need to ensure that the above design guidelines are followed.

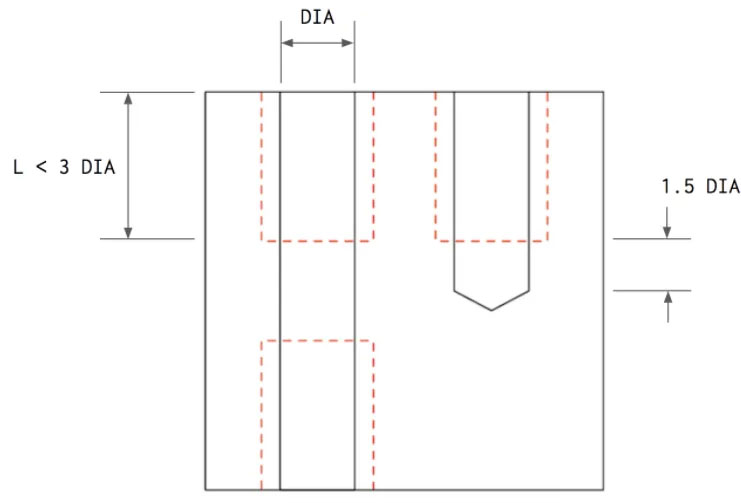

4, R&D Cost Reduction #4 – Reduce Thread Depth

Unnecessary thread depth increases CNC machining costs because specialized tooling is required.

Remember: Excessive thread depth (more than 3 times the hole diameter) does not increase the strength of the connection.

To reduce costs:

+ The thread depth can be up to 3 times the screw hole diameter.

+ For blind hole tapping, it is best to add at least 1/2 hole thread diameter extra length at the hole root.

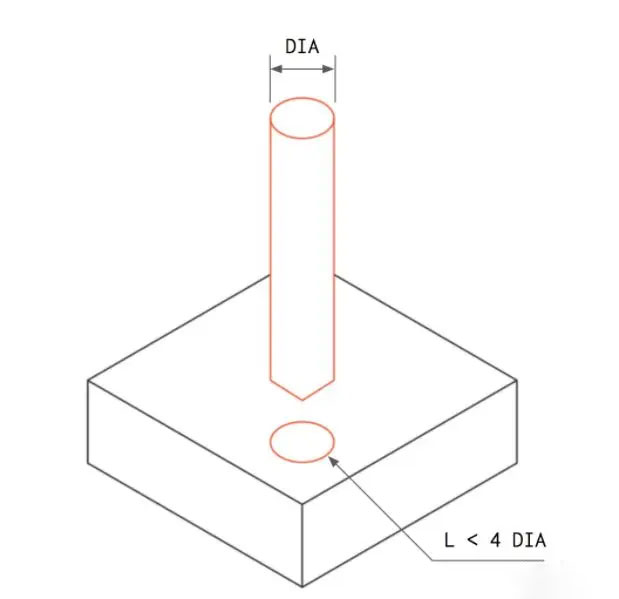

5, R&D Cost Reduction #5 — Designing Holes with Standard Sizes

Using a standard drill bit, holes can be machined quickly and accurately; for non-standard holes, using an end mill will increase costs.

In addition, the depth of the hole should not exceed 4 times its diameter. Deep holes (up to 10 times the diameter) can be machined, but this will increase the cost significantly due to the difficulty of machining.

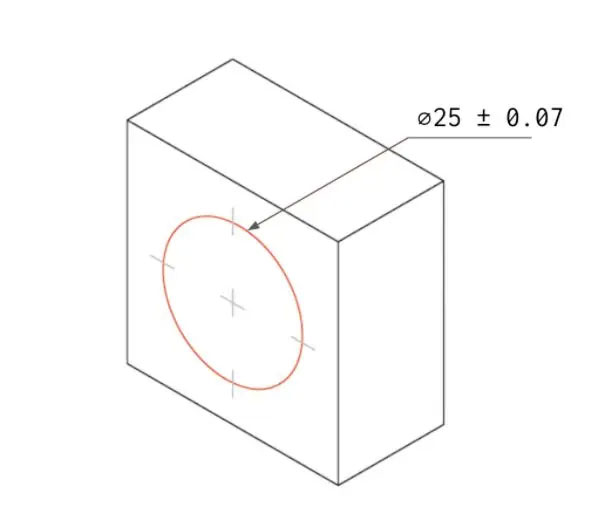

6, R&D Cost Reduction #6 – Avoid Tight Tolerance Requirements

Close tolerance requirements increase costs because they require complex machining operations, increase machining time, and require more inspections.

When defining part size tolerances, you must be careful to avoid marking tolerances on any dimensions. Tolerances should be marked only when necessary, and precise tolerances should be marked only when absolutely necessary.

If tolerances are not defined in the part drawing, the part will be machined to standard tolerances (± 0.2mm or looser), which is sufficient for most non-critical dimensions and can significantly reduce machining costs.

For internal features, precise tolerances are more difficult to maintain. For example, when machining intersecting holes or slots, small defects such as burrs are likely to appear on the edges due to deformation caused by stress.

These features require inspection and deburring processes, which can only be performed manually, which is labor-intensive, time-consuming, and therefore costly.

To reduce costs:

+ Define close tolerances only as a last resort.

+ All dimensions are marked using the same datum.

+ Remember : The decimal points in the tolerance are important; they define the degree of precision and the type of measuring tool required. For example, a two-decimal-point measurement can be done with a vernier caliper, while a three-decimal-point measurement can be done with a micrometer or a CMM. To reduce costs, avoid adding unnecessary decimal points.

+ Precise tolerance requirements can be avoided through optimized product design, such as shortening the dimensional chain and using positioning features. For details, please refer to Chapter 7 of the book “Product Guide for Manufacturing and Assembly”.

7, R&D Cost Reduction #7 – Reduce the number of clamping times

Minimize the number of times parts are clamped, preferably only once.

For example, a part with blind holes on both sides requires two clampings. After one side is processed, it must be rotated and re-clamped before the other side can be processed.

Rotating or repositioning the part increases machining costs, as clamping is typically performed manually. Furthermore, complex part configurations require custom fixtures, further increasing costs. Particularly complex configurations may require a multi-axis CNC machine, further increasing costs due to the high hourly rates of multi-axis CNC machines.

It is possible to consider dividing the complex part structure into multiple parts for CNC machining, and then fastening them into one by threading or welding.

To reduce costs:

+ Designed parts only need to be clamped once.

+ If this is not possible, separate complex parts into multiple parts and fasten them into one piece through subsequent processes.

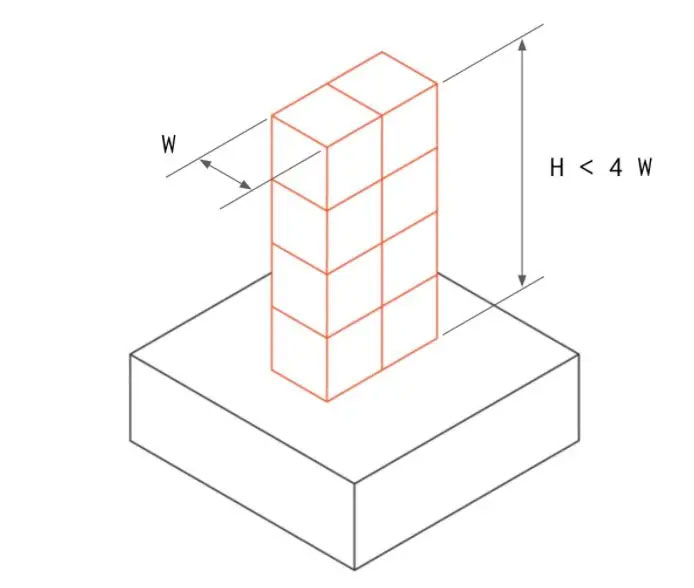

8, R&D Cost Reduction #8 – Avoid Small Features with Large Aspect Ratios

During CNC machining, some small features with large aspect ratios are prone to vibration, making them difficult to machine accurately.

To avoid this, these small features should be connected to some thicker walls or supported by some reinforcing ribs.

To reduce costs:

+ Avoid designing features with an aspect ratio exceeding 4.

+ Connect small features to thicker walls or add ribs for support.

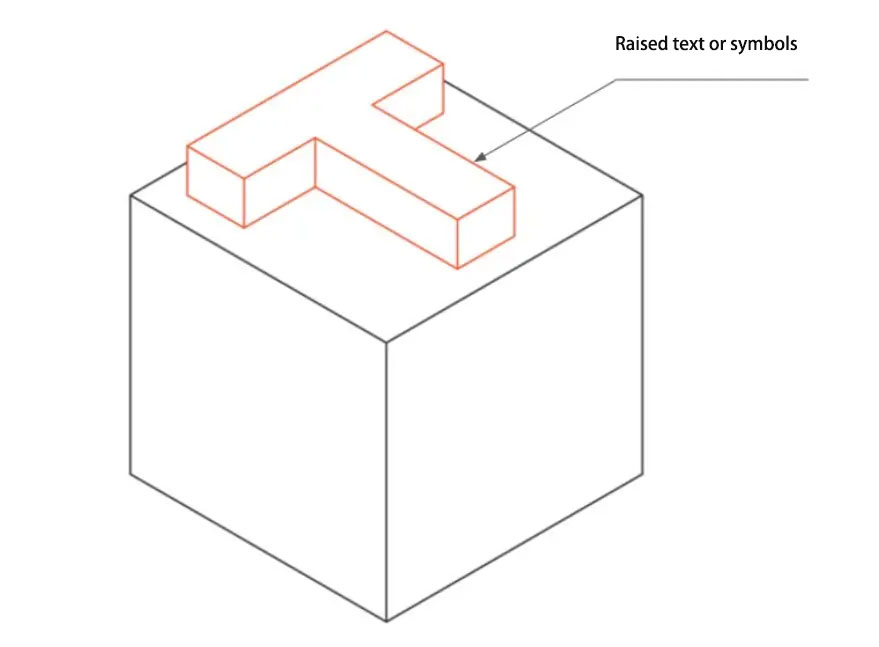

9, R&D Cost Reduction #9 – Removing Text and Symbols from Part Surfaces

Text and symbols on the surface of the part will significantly increase CNC costs because they require additional machining steps and consume more machining time.

Text and symbols can be added to CNC parts using some surface treatment techniques, such as silk screen or painting, which is a more cost-effective method.

To reduce costs:

+ Remove all text and symbols on the surface of parts;

+ If text and symbols are necessary, choose recessed rather than raised, as the latter requires more material removal.

10, R&D Cost Reduction #10 – Consider the Processability of Materials

The processability of a material refers to the ease or difficulty of processing the material.

The better the processability, the easier it is to CNC machine the parts and the lower the cost.

The machinability of a material depends on its physical properties. Generally speaking, the softer and more ductile the material, the easier it is to machine.

For example, brass C360 has the highest processability and can be processed at high speeds; aluminum alloys (aluminum 6061 and 7075) can also be easily processed.

Steel has a very low processability, requiring more than twice the processing time of aluminum alloys. Of course, the processability of different steels varies. The processability index of 304 stainless steel is 45%, while that of 303 stainless steel is 78%, making the latter easier to process.

The processing performance of plastic materials depends on their stiffness and thermal properties. During CNC machining, plastic materials are easily melted and deformed at high temperatures.

POM is the easiest material to CNC process, followed by ABS; PEEK and nylon are common engineering plastic materials that are difficult to process.

To reduce costs:

+ Whenever possible, try to choose materials with good processing properties.

11, R&D Cost Reduction #11 – Consider the Price of Raw Materials

Raw material billet price is another key factor in CNC cost.

The table below shows prices for common metal and plastic raw material blanks with a size of 150 x 150 x 25 mm.

| raw materials | Billet price (values are for comparison only) |

| Aluminum 6061 | ¥170 |

| Aluminum 7075 | ¥ 540 |

| Stainless steel 304 | ¥ 610 |

| Stainless steel 303 | ¥ 1000 |

| Brass C360 | RMB 1006 |

| ABS | ¥ 115 |

| Nylon 6 | ¥ 204 |

| POM | ¥ 180 |

| PEEK | ¥ 2000 |

Aluminum 6061 is obviously a very cost-effective material. Not only is the billet price low, but the processing technology is also good, which is very suitable for making prototypes.

Stainless steel 303 and brass C360 also have excellent processing properties, with high efficiency and short processing time. However, the billet price is very high, so it is only suitable for large-scale production. Through the batch effect, the high billet price is balanced by the short processing time.

Plastic materials such as ABS, nylon, and POM are similar in price to aluminum 6061. However, they are more difficult to machine and therefore more expensive to CNC. PEEK is a very expensive material and should only be used when necessary.

To reduce costs:

+ Choose materials with low billet prices whenever possible, especially when the batch size is small.

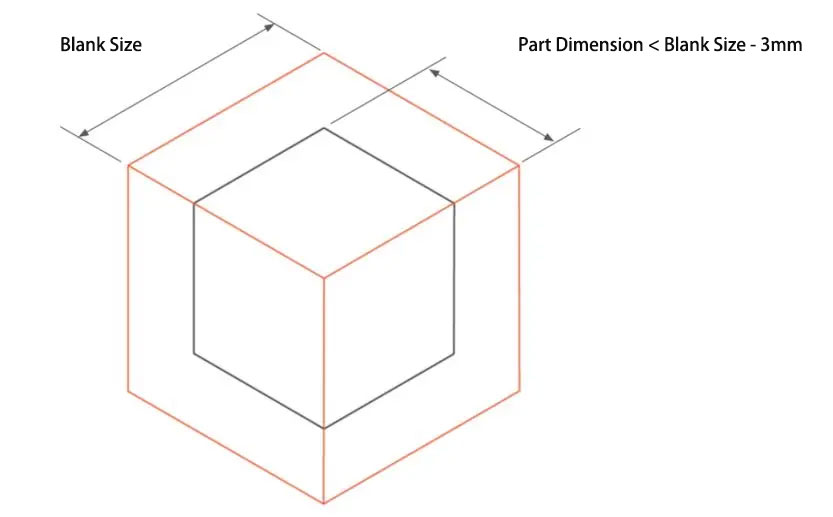

12, R&D Cost Reduction #12 – Consider Billet Size

Blank size affects CNC costs: to ensure dimensional accuracy, material must be removed from all sides of the part, which can significantly increase material costs, especially in larger batches.

Generally speaking, the blank size should be at least 3mm larger than the part. For example, if the outer dimensions of a part are 30X30X30mm, then a blank size of 35X35X35mm can be selected; if the outer dimensions are 27X27X27mm, then a blank size of 30X30X30mm can be selected, which can save some material costs.

To reduce costs:

+ The blank size is generally at least 3mm larger than the part size.

+ You can consult the supplier for standard billet size specifications and try to design the parts close to the billet size specifications to reduce material waste.

13, R&D Cost Reduction #13 – Avoid Multiple Surface Treatments

Surface treatment can improve the appearance of CNC parts and increase their ability to withstand harsh environments, but it also increases costs.

If the CNC part requires multiple different surface finishes, this can further increase costs because more steps are required, such as masking some surfaces.

To reduce costs:

+ Cancel surface treatment.

+ Avoid multiple surface treatments.

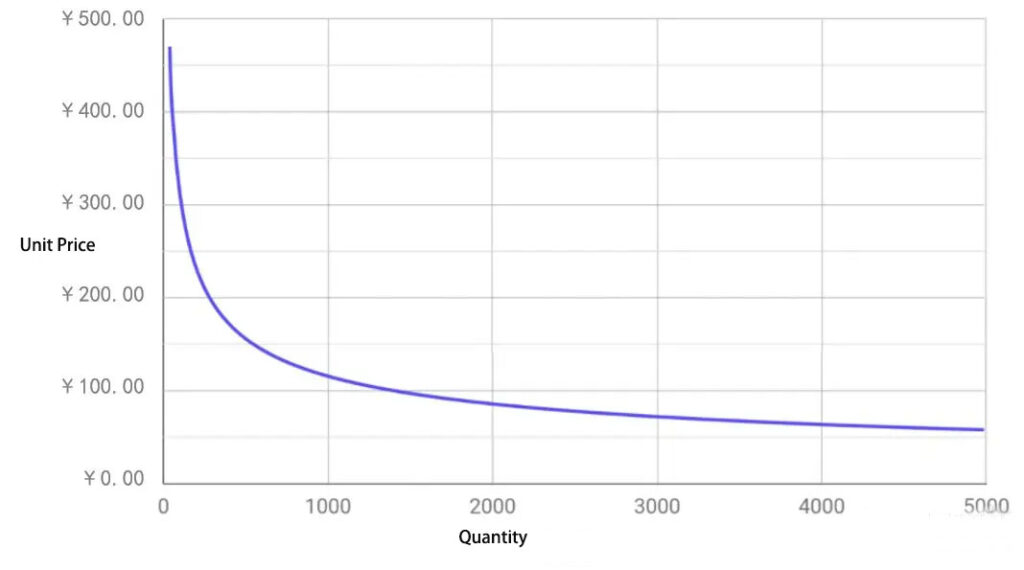

14, R&D Cost Reduction #14 – Mass Production

In CNC machining, part batch size affects machining costs because the initial setup cost of CNC machining is higher per part when batch size is smaller. When batch size is larger, the setup cost per part is lower.

CNC costs decrease with larger part batches, and this is especially true when part batches are small: even a small increase in quantity can significantly reduce costs.

The part batch size increased from 1 to 5, and the part cost was reduced by more than 50%.

To reduce costs:

+ High-volume production reduces costs and allows you to place a larger order rather than multiple, scattered orders.

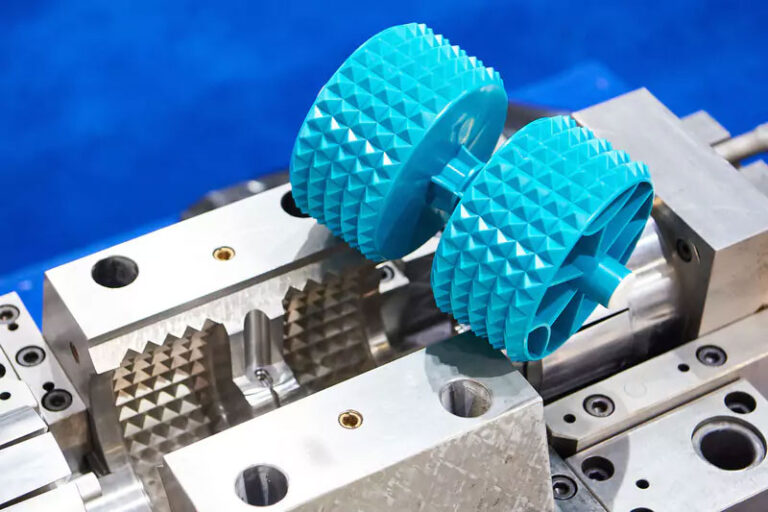

16, R&D Cost Reduction #15 – Designing Axially Symmetric Parts

Axially symmetrical parts can be machined using lathes or milling machines, with machine hour rates much lower than 3- or 5-axis machining centers.

To reduce costs:

+ Try to design axisymmetric parts.

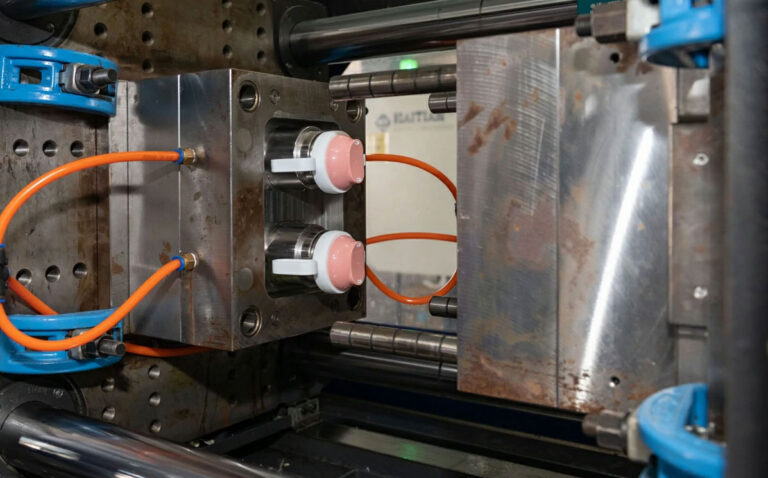

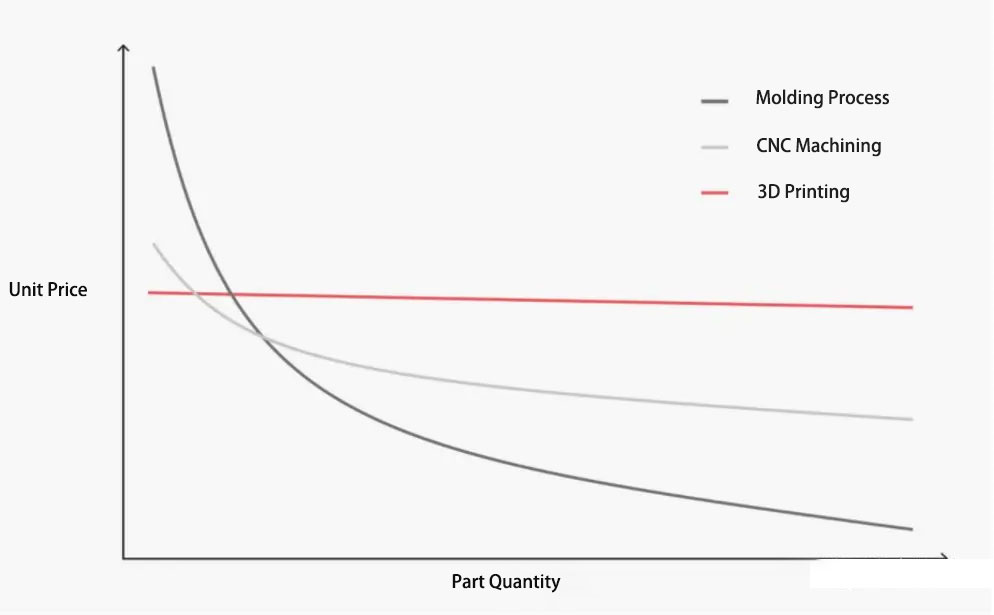

As shown in the figure below, when the batch size is small, the cost of 3D printing is lower than CNC machining; when the batch size is large, the cost of molding processes such as investment casting and injection molding is lower than CNC machining.

As a professional rapid prototyping manufacturer, we dare say that:

There is always someone better out there, and the next process will be even better.

In many cases, 3D printing is better than CNC machining:

- 3D printing can process parts with more complex geometries.

- 3D printing can provide samples within 24 hours.

- 3D printing is generally cheaper when the quantity is small.

- 3D printing can process materials that are difficult to process with CNC, such as super alloys.

To reduce costs:

+ Use other processes instead of CNC.

Note: The same is true for any other manufacturing and fastening processes, including injection molding, stamping, welding, and riveting. When selecting a process in the early stages of product design, recite the ancient poem “There is always fragrant grass everywhere in the world, and the next process will be better” many times in your mind. Try hard to find it. There must be a better process, but you just don’t know it now.

Final Words

Reducing R&D costs is a very challenging task, and Chinese engineers generally lack knowledge in this area. During my first few years of actual product development experience, I rarely considered cost during design. I unilaterally prioritized “customer first” and “customer first.” Engineers’ primary responsibility was to meet customer needs, leaving cost management to the manufacturing department.

This is a misconception of product costs:

1) Product cost plays a very important role in product development

As Integrated Product Development (IPD) advocates, product development is an investment. If a company fails to generate profit or even loses money due to excessively high product costs, even if customers are satisfied with the product, such product development is a complete waste of financial and human resources, generating no value. Under such circumstances, the company will eventually be eliminated.

2) More than 85% of product costs are determined by product design, and the remaining 15% is determined by product manufacturing

If cost-oriented product design is not carried out during product design, the final production cost of the product will inevitably be too high.

To conduct cost-oriented product design, companies and engineers must first change their mindset and improve their cost awareness. When one day engineers spend “long nights without sleep” for every detail of product design, for example:

+ Should the part wall thickness be 4mm or 5mm?

+ Should the radius be designed to be 0.3mm or 0.5mm?

+ Should the tolerance of important dimensions be 0.05mm or 0.1mm?

It can be said that engineers have a preliminary awareness of costs.

Without such cost awareness, an engineer is not an engineer, but just a draftsman who can use Creo, UG or Solidworks.

If engineers do not make changes, do not work hard to learn, and only position themselves as draftsmen, they will never achieve a breakthrough in their careers and will wake up one day in the future to find that their jobs will be replaced by AI.

There are also engineers who believe that costs are the company’s business, and whether the company is profitable or not has little to do with them.In this regard, I can only hope that you will not be laid off when the company downsizes.