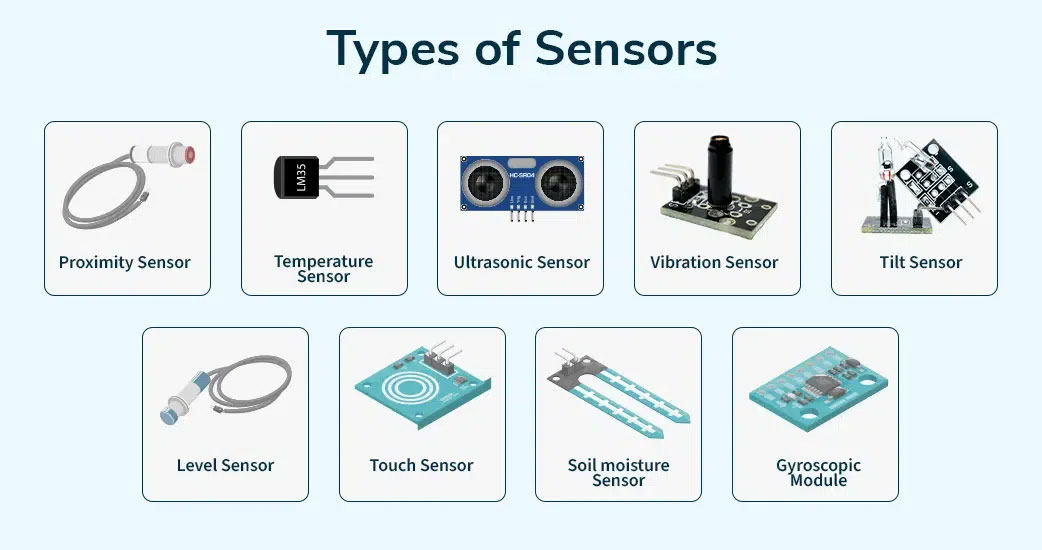

In mechanical design, sensors are key components for achieving automation, intelligence, and precise control. The following are the top ten sensor types commonly used in mechanical design and their application scenarios:

1, Magnetic switch

Function: Detect the cylinder piston position and feedback the piston movement stroke.

Application: Used in pneumatic control systems, such as cylinder position detection in automated production lines.

2, Proximity switch

Function: Detects the presence or distance of metal objects, suitable for non-contact detection. Non-contact detection features reliable operation, stable performance, high precision, fast response, long service life, strong anti-interference capabilities, and is waterproof, shockproof, and corrosion-resistant.

Application: Material counting and equipment arrival detection, but the detection distance is affected by the material.

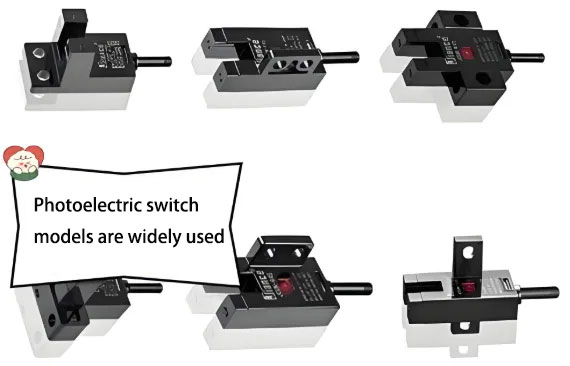

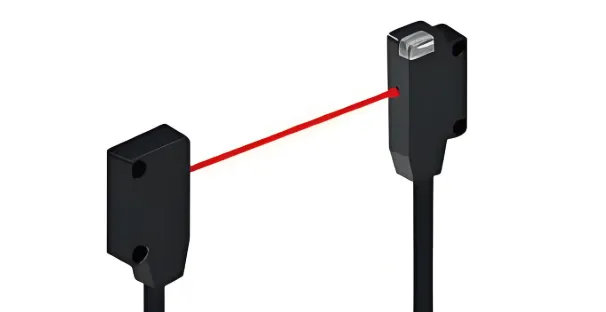

3, Photoelectric sensor

Slot-type photoelectric switch: used for detecting the extreme position of rotation or linear motion.

Diffuse reflection photoelectric switch: detects the presence of packaging materials.

Through-beam photoelectric switch: suitable for long-distance detection, such as logistics sorting.

Application: automated packaging, material testing.

4, Fiber Optic Sensors

Features: High sensitivity, compact structure, suitable for detecting small changes.

Application: precision manufacturing, micro-displacement measurement.

5, Pressure sensor

Function: Measure fluid or gas pressure.

Application: stamping machine pressure monitoring, logistics weighing system.

6, Light barrier sensor (safety light curtain)

Function: Forms a protective barrier through infrared beams to prevent mechanical damage.

Application: Industrial safety protection, such as machine tool operating area monitoring.

7, Displacement sensor

Types: Includes linear displacement sensors and rotary encoders.

Applications: Robot arm positioning, CNC machine tool feedback control.

8, Force/Torque Sensor

Function: Monitor force and torque of a robotic arm or drive system.

Applications: collaborative robots, precision assembly.

9, Temperature sensor

Function: Monitor device or environment temperature.

Application: Metal processing, injection molding temperature control.

10, Vision Sensors

2D vision: used for object recognition and positioning.

3D vision: used for modeling complex objects.

Application: automated sorting, quality inspection.

These sensors are widely used in mechanical design in fields such as automation control, safety monitoring, and quality inspection, and are key components for realizing intelligent manufacturing.